GENOSYL- nitric oxide gas

GENOSYL by

Drug Labeling and Warnings

GENOSYL by is a Prescription medication manufactured, distributed, or labeled by VERO BIOTECH, INC.. Drug facts, warnings, and ingredients follow.

Drug Details [pdf]

-

HIGHLIGHTS OF PRESCRIBING INFORMATION

These highlights do not include all the information needed to use GENOSYL ®safely and effectively. See full prescribing information for GENOSYL.

GENOSYL (nitric oxide), for inhalation use

Initial U.S. Approval: 1999INDICATIONS AND USAGE

GENOSYL is a vasodilator indicated to improve oxygenation and reduce the need for extracorporeal membrane oxygenation in term and near-term (>34 weeks gestation) neonates with hypoxic respiratory failure associated with clinical or echocardiographic evidence of pulmonary hypertension in conjunction with ventilatory support and other appropriate agents ( 1).

DOSAGE AND ADMINISTRATION

The recommended dose is 20 ppm, maintained for up to 14 days or until the underlying oxygen desaturation has resolved ( 2.1).

DOSAGE FORMS AND STRENGTHS

GENOSYL (nitric oxide) is a gas, available at concentrations up to 800 ppm. (3)

CONTRAINDICATIONS

Neonates dependent on right-to-left shunting of blood ( 4).

WARNINGS AND PRECAUTIONS

Rebound Pulmonary Hypertension: Abrupt discontinuation of GENOSYL may lead to worsening oxygenation and increasing pulmonary artery pressure ( 5.1).

Methemoglobinemia: Methemoglobin increases with the dose of nitric oxide; following discontinuation or reduction of nitric oxide, methemoglobin levels return to baseline over a period of hours ( 5.2).

Elevated NO 2Levels: Monitor NO 2levels ( 5.3).

Heart Failure: In patients with pre-existing left ventricular dysfunction, GENOSYL may increase pulmonary capillary wedge pressure leading to pulmonary edema ( 5.4).

ADVERSE REACTIONS

The most common adverse reaction is hypotension ( 6).

To report SUSPECTED ADVERSE REACTIONS, contact Vero Biotech at 1-877-337-4118 and http://www.vero-biotech.com/ or FDA at 1-800-FDA-1088 or www.fda.gov/medwatch.

DRUG INTERACTIONS

Nitric oxide donor compounds may increase the risk of developing methemoglobinemia ( 7).

Revised: 8/2024

-

Table of Contents

FULL PRESCRIBING INFORMATION: CONTENTS*

1 INDICATIONS AND USAGE

2 DOSAGE AND ADMINISTRATION

2.1 Dosage

2.2 Administration

3 DOSAGE FORMS AND STRENGTHS

4 CONTRAINDICATIONS

5 WARNINGS AND PRECAUTIONS

5.1 Rebound Pulmonary Hypertension Syndrome following Abrupt Discontinuation

5.2 Hypoxemia from Methemoglobinemia

5.3 Airway Injury from Nitrogen Dioxide

5.4 Worsening Heart Failure

6 ADVERSE REACTIONS

6.1 Clinical Trials Experience

6.2 Postmarketing Experience

7 DRUG INTERACTIONS

7.1 Nitric Oxide Donor Agents

8 USE IN SPECIFIC POPULATIONS

8.4 Pediatric Use

8.5 Geriatric Use

10 OVERDOSAGE

11 DESCRIPTION

12 CLINICAL PHARMACOLOGY

12.1 Mechanism of Action

12.2 Pharmacodynamics

12.3 Pharmacokinetics

13 NONCLINICAL TOXICOLOGY

13.1 Carcinogenesis, Mutagenesis, Impairment of Fertility

14 CLINICAL STUDIES

14.1 Treatment of Hypoxic Respiratory Failure (HRF)

14.2 Ineffective in Adult Respiratory Distress Syndrome (ARDS)

14.3 Ineffective in Prevention of Bronchopulmonary Dysplasia (BPD)

16 HOW SUPPLIED/STORAGE AND HANDLING

- * Sections or subsections omitted from the full prescribing information are not listed.

-

1 INDICATIONS AND USAGE

GENOSYL ®is indicated to improve oxygenation and reduce the need for extracorporeal membrane oxygenation in term and near-term (>34 weeks gestation) neonates with hypoxic respiratory failure associated with clinical or echocardiographic evidence of pulmonary hypertension in conjunction with ventilatory support and other appropriate agents.

-

2 DOSAGE AND ADMINISTRATION

2.1 Dosage

Term and near-term neonates with hypoxic respiratory failure

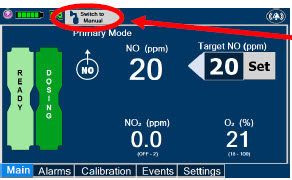

The recommended dose of GENOSYL is 20 ppm. Maintain treatment up to 14 days or until the underlying oxygen desaturation has resolved and the neonate is ready to be weaned from GENOSYL therapy.

Doses greater than 20 ppm are not recommended [see Warnings and Precautions (5.2)].

2.2 Administration

Nitric Oxide Delivery System

GENOSYL must be administered using a calibrated GENOSYL Delivery System. Only validated ventilator systems should be used in conjunction with GENOSYL [see Description (11)].

Consult the GENOSYL Delivery System Operator's Manual or call 1-877-337-4118 or visit www.vero-biotech.com for needed information on training and technical support for users of GENOSYL with the GENOSYL Delivery System .

Keep available a backup power supply to address power failures. The GENOSYL Delivery System consists of a primary system and a fully functional second system that can be used as backup in the event of primary system failure.

Monitoring

Measure methemoglobin within 4-8 hours after initiation of treatment with GENOSYL and periodically throughout treatment [see Warnings and Precautions (5.2)].

Monitor for PaO 2and inspired NO 2during GENOSYL administration [see Warnings and Precautions 5.3)].

Weaning and Discontinuation

Avoid abrupt discontinuation of GENOSYL [see Warnings and Precautions (5.1)]. To wean GENOSYL, down titrate in several steps, pausing several hours at each step to monitor for hypoxemia.

- 3 DOSAGE FORMS AND STRENGTHS

- 4 CONTRAINDICATIONS

-

5 WARNINGS AND PRECAUTIONS

5.1 Rebound Pulmonary Hypertension Syndrome following Abrupt Discontinuation

Wean from GENOSYL [see Dosage and Administration (2.2)]. Abrupt discontinuation of GENOSYL may lead to worsening oxygenation and increasing pulmonary artery pressure, i.e., Rebound Pulmonary Hypertension Syndrome. Signs and symptoms of Rebound Pulmonary Hypertension Syndrome include hypoxemia, systemic hypotension, bradycardia, and decreased cardiac output. If Rebound Pulmonary Hypertension occurs, reinstate GENOSYL therapy immediately.

5.2 Hypoxemia from Methemoglobinemia

Nitric oxide combines with hemoglobin to form methemoglobin, which does not transport oxygen. Methemoglobin levels increase with the dose of GENOSYL; it can take 8 hours or more before steady-state methemoglobin levels are attained. Monitor methemoglobin and adjust the dose of GENOSYL to optimize oxygenation.

If methemoglobin levels do not resolve with decrease in dose or discontinuation of GENOSYL, additional therapy may be warranted to treat methemoglobinemia [see Overdosage (10)] .

5.3 Airway Injury from Nitrogen Dioxide

Nitrogen dioxide (NO 2) forms in gas mixtures containing NO and O 2. Nitrogen dioxide may cause airway inflammation and damage to lung tissues.

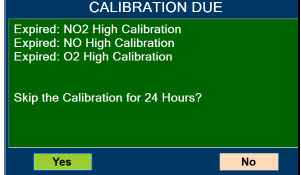

If there is an unexpected change in NO 2concentration, or if the NO 2concentration reaches 0.5 ppm when measured in the breathing circuit, then the delivery system should be assessed in accordance with the GENOSYL Delivery System Operator's Manual troubleshooting section, and the NO 2analyzer should be recalibrated. The dose of GENOSYL and/or FiO 2should be adjusted as appropriate.

5.4 Worsening Heart Failure

Patients with left ventricular dysfunction treated with GENOSYL may experience pulmonary edema, increased pulmonary capillary wedge pressure, worsening of left ventricular dysfunction, systemic hypotension, bradycardia and cardiac arrest. Discontinue GENOSYL while providing symptomatic care.

-

6 ADVERSE REACTIONS

The following adverse reactions are discussed elsewhere in the label;

Hypoxemia [see Warnings and Precautions (5.2)]

Worsening Heart Failure [see Warnings and Precautions (5.4)]

6.1 Clinical Trials Experience

Because clinical trials are conducted under widely varying conditions, adverse reaction rates observed in the clinical trials of a drug cannot be directly compared to rates in the clinical trials of another drug and may not reflect the rates observed in practice. The adverse reaction information from the clinical studies does, however, provide a basis for identifying the adverse events that appear to be related to drug use and for approximating rates.

Controlled studies have included 325 patients on nitric oxide doses of 5 to 80 ppm and 251 patients on placebo. Total mortality in the pooled trials was 11% on placebo and 9% on nitric oxide gas for inhalation, a result adequate to exclude nitric oxide mortality being more than 40% worse than placebo.

In both the NINOS and CINRGI studies, the duration of hospitalization was similar in nitric oxide gas for inhalation and placebo-treated groups.

From all controlled studies, at least 6 months of follow-up is available for 278 patients who received nitric oxide gas and 212 patients who received placebo. Among these patients, there was no evidence of an adverse effect of treatment on the need for re-hospitalization, special medical services, pulmonary disease, and neurological sequelae.

In the NINOS study, treatment groups were similar with respect to the incidence and severity of intracranial hemorrhage, Grade IV hemorrhage, periventricular leukomalacia, cerebral infarction, seizures requiring anticonvulsant therapy, pulmonary hemorrhage, or gastrointestinal hemorrhage.

In CINRGI, the only adverse reaction (>2% higher incidence on nitric oxide gas for inhalation than on placebo) was hypotension (14% vs. 11%).

- 7 DRUG INTERACTIONS

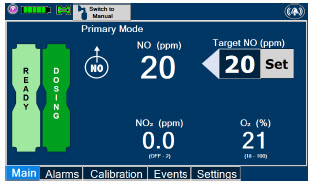

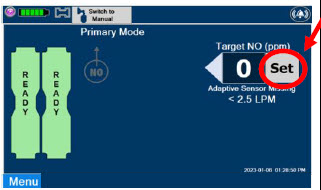

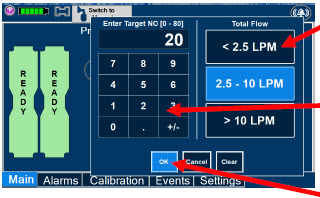

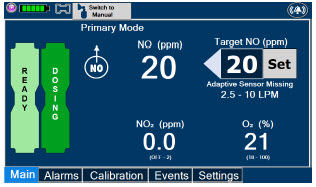

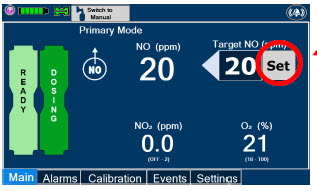

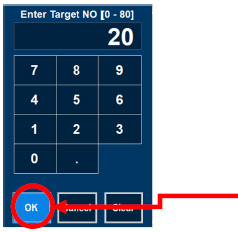

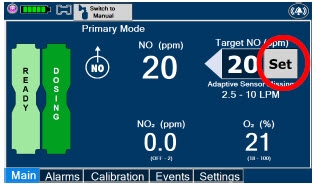

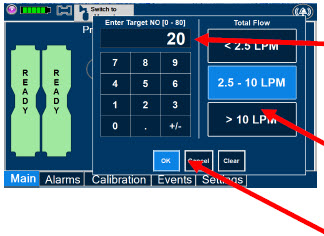

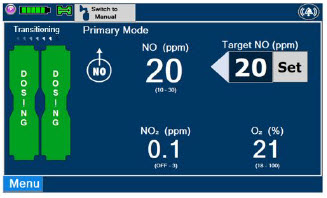

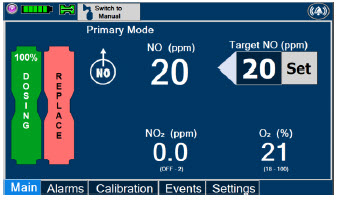

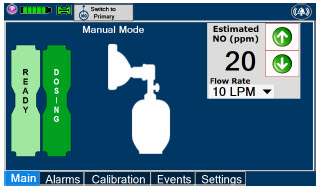

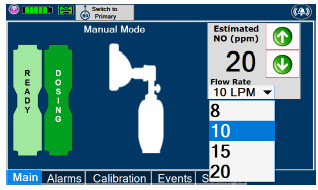

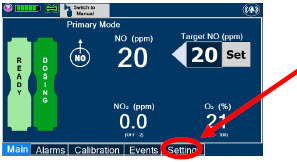

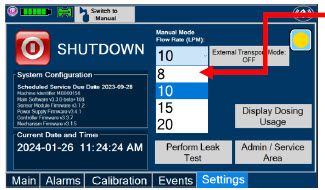

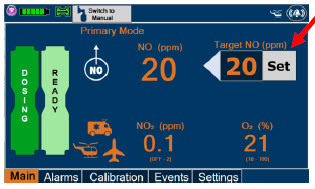

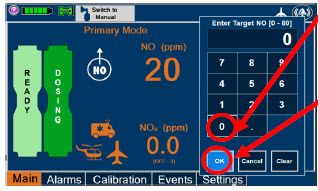

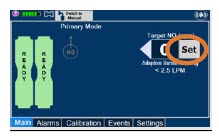

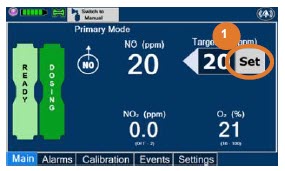

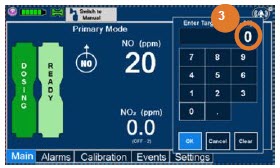

-

8 USE IN SPECIFIC POPULATIONS

8.4 Pediatric Use

The safety and efficacy of nitric oxide for inhalation has been demonstrated in term and near-term neonates with hypoxic respiratory failure associated with evidence of pulmonary hypertension [see Clinical Studies (14.1)] . Additional studies conducted in premature neonates for the prevention of bronchopulmonary dysplasia have not demonstrated substantial evidence of efficacy [see Clinical Studies (14.3)]. No information about its effectiveness in other age populations is available.

-

10 OVERDOSAGE

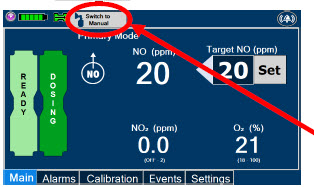

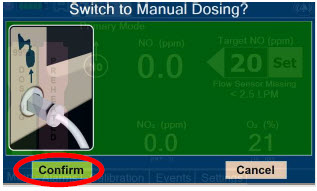

Overdosage with nitric oxide gas is manifest by elevations in methemoglobin and pulmonary toxicities associated with inspired NO 2. Elevated NO 2may cause acute lung injury. Elevations in methemoglobin reduce the oxygen delivery capacity of the circulation. In clinical studies, NO 2levels >3 ppm or methemoglobin levels >7% were treated by reducing the dose of, or discontinuing, nitric oxide gas.

Methemoglobinemia that does not resolve after reduction or discontinuation of therapy can be treated with intravenous vitamin C, intravenous methylene blue, or blood transfusion, based upon the clinical situation.

-

11 DESCRIPTION

GENOSYL (nitric oxide) is administered by inhalation. Nitric oxide is a pulmonary vasodilator. Nitric oxide is generated from liquid dinitrogen tetroxide (N 2O 4) by the Cassette in the GENOSYL Delivery System. Upon initiation of GENOSYL Delivery System, the liquid N 2O 4is heated and the equilibrium shifts to nitrogen dioxide (NO 2) gas. The NO 2is then converted into nitric oxide (NO) using the antioxidant Cartridges, and nitric oxide is delivered to the patient by means of a ventilator or a nasal cannula. The amount of nitric oxide administered to the patient is set by controlling the temperature of the N 2O 4liquid module, which controls the pressure inside the liquid module, which in turn controls the mass of NO 2that is sent to the primary Cartridges, and hence the mass of nitric oxide. The mass flow of nitric oxide, together with the air from the pump, control the nitric oxide concentration. A nitric oxide sensor monitors the nitric oxide in the patient line. GENOSYL Delivery System is designed to deliver a controlled level of nitric oxide blended with breathing air or oxygen-enriched breathing air.

The GENOSYL Delivery System controls the flow of nitric oxide mixed with air delivered to the patient.

The structural formula of nitric oxide (NO) is shown below:

-

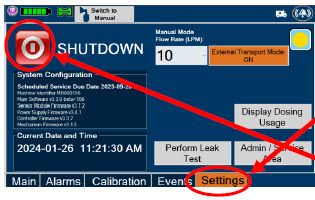

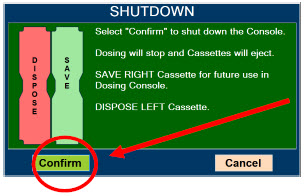

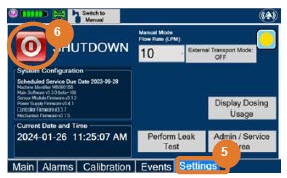

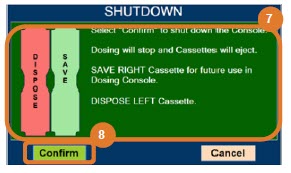

12 CLINICAL PHARMACOLOGY

12.1 Mechanism of Action

Nitric oxide relaxes vascular smooth muscle by binding to the heme moiety of cytosolic guanylate cyclase, activating guanylate cyclase and increasing intracellular levels of cyclic guanosine 3',5'-monophosphate, which then leads to vasodilation. When inhaled, nitric oxide selectively dilates the pulmonary vasculature, and because of efficient scavenging by hemoglobin, has minimal effect on the systemic vasculature.

GENOSYL appears to increase the partial pressure of arterial oxygen (PaO 2) by dilating pulmonary vessels in better ventilated areas of the lung, redistributing pulmonary blood flow away from lung regions with low ventilation/perfusion (V/Q) ratios toward regions with normal ratios.

12.2 Pharmacodynamics

Effects on Pulmonary Vascular Tone in PPHN

Persistent pulmonary hypertension of the newborn (PPHN) occurs as a primary developmental defect or as a condition secondary to other diseases such as meconium aspiration syndrome (MAS), pneumonia, sepsis, hyaline membrane disease, congenital diaphragmatic hernia (CDH), and pulmonary hypoplasia. In these states, pulmonary vascular resistance (PVR) is high, which results in hypoxemia secondary to right-to-left shunting of blood through the patent ductus arteriosus and foramen ovale. In neonates with PPHN, nitric oxide gas for inhalation improves oxygenation (as indicated by significant increases in PaO 2).

12.3 Pharmacokinetics

The pharmacokinetics of nitric oxide has been studied in adults.

Absorption and Distribution

Nitric oxide is absorbed systemically after inhalation. Most of it traverses the pulmonary capillary bed where it combines with hemoglobin that is 60% to 100% oxygen-saturated. At this level of oxygen saturation, nitric oxide combines predominantly with oxyhemoglobin to produce methemoglobin and nitrate. At low oxygen saturation, nitric oxide can combine with deoxyhemoglobin to transiently form nitrosylhemoglobin, which is converted to nitrogen oxides and methemoglobin upon exposure to oxygen. Within the pulmonary system, nitric oxide can combine with oxygen and water to produce nitrogen dioxide and nitrite, respectively, which interact with oxyhemoglobin to produce methemoglobin and nitrate. Thus, the end products of nitric oxide that enter the systemic circulation are predominantly methemoglobin and nitrate.

Metabolism

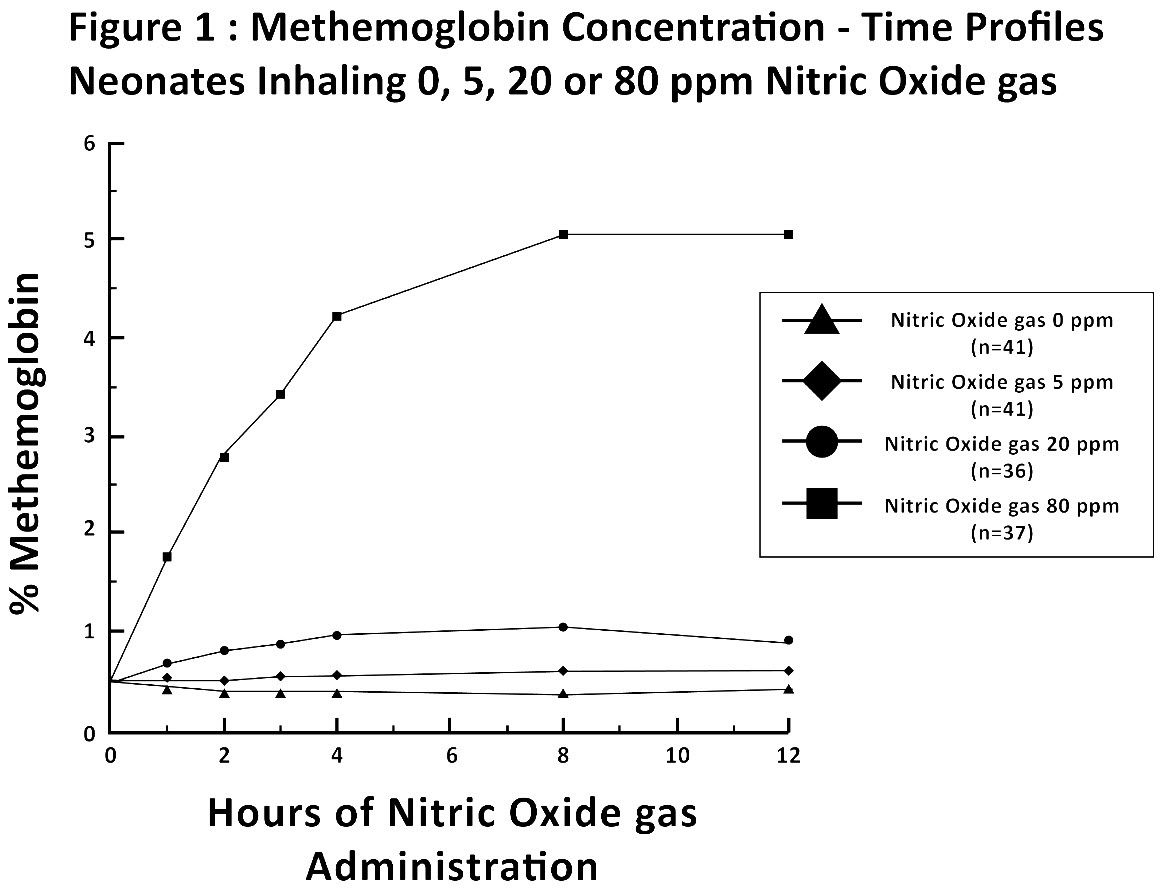

Methemoglobin disposition has been investigated as a function of time and nitric oxide exposure concentration in neonates with respiratory failure. The methemoglobin (MetHb) concentration-time profiles during the first 12 hours of exposure to 0, 5, 20, and 80 ppm nitric oxide are shown in Figure 1.

Methemoglobin concentrations increased during the first 8 hours of nitric oxide exposure. The mean methemoglobin level remained below 1% in the placebo group and in the 5 ppm and 20 ppm nitric oxide gas groups, but reached approximately 5% in the 80 ppm nitric oxide gas group. Methemoglobin levels >7% were attained only in patients receiving 80 ppm, where they comprised 35% of the group. The average time to reach peak methemoglobin was 10 ± 9 (SD) hours (median, 8 hours) in these 13 patients, but one patient did not exceed 7% until 40 hours.

-

13 NONCLINICAL TOXICOLOGY

13.1 Carcinogenesis, Mutagenesis, Impairment of Fertility

No evidence of a carcinogenic effect was apparent, at inhalation exposures up to the recommended dose (20 ppm), in rats for 20 hr/day for up to two years. Higher exposures have not been investigated.

Nitric oxide gas has demonstrated genotoxicity in Salmonella (Ames Test), human lymphocytes, and after in vivo exposure in rats. There are no animal or human studies to evaluate nitric oxide for effects on fertility.

-

14 CLINICAL STUDIES

14.1 Treatment of Hypoxic Respiratory Failure (HRF)

The efficacy of nitric oxide gas was investigated in term and near-term newborns with hypoxic respiratory failure (HRF) resulting from a variety of etiologies. Inhalation of nitric oxide gas reduces the oxygenation index (OI= mean airway pressure in cm H 2O × fraction of inspired oxygen concentration [FiO 2]× 100 divided by systemic arterial concentration in mmHg [PaO 2]) and increases PaO 2[see Clinical Pharmacology (12.1)].

NINOS Study

The Neonatal Inhaled Nitric Oxide Study (NINOS) was a double-blind, randomized, placebo-controlled, multicenter trial in 235 neonates with hypoxic respiratory failure. The objective of the study was to determine whether inhaled nitric oxide would reduce the occurrence of death and/or initiation of extracorporeal membrane oxygenation (ECMO) in a prospectively defined cohort of term or near-term neonates with hypoxic respiratory failure unresponsive to conventional therapy. Hypoxic respiratory failure was caused by meconium aspiration syndrome (MAS; 49%), pneumonia/sepsis (21%), idiopathic primary pulmonary hypertension of the newborn (PPHN; 17%), or respiratory distress syndrome (RDS; 11%). Infants ≤14 days of age (mean, 1.7 days) with a mean PaO 2of 46 mmHg and a mean oxygenation index (OI) of 43 cm H 2O / mmHg were initially randomized to receive 100% O 2with (n=114) or without (n=121) 20 ppm nitric oxide for up to 14 days. Response to study drug was defined as a change from baseline in PaO 230 minutes after starting treatment (full response = >20 mmHg, partial = 10–20 mmHg, no response = <10 mmHg). Neonates with a less than full response were evaluated for a response to 80 ppm nitric oxide or control gas. The primary results of this study are presented in Table 1.

Table 1: Summary of Clinical Results from Hypoxic Respiratory Failure Study Control

(n=121)Nitric Oxide gas (n=114) P value - * Extracorporeal membrane oxygenation

- † Death or need for ECMO was the primary end point of this study

Death or ECMO *,† 77 (64%) 52 (46%) 0.006 Death 20 (17%) 16 (14%) 0.60 ECMO 66 (55%) 44 (39%) 0.014 Although the incidence of death by 120 days of age was similar in both groups (NO, 14%; control 17%), significantly fewer infants in the nitric oxide group required ECMO compared with controls (39% vs. 55%, p = 0.014). The combined incidence of death and/or initiation of ECMO showed a significant advantage for the nitric oxide treated group (46% vs. 64%, p = 0.006). The nitric oxide group also had significantly greater increases in PaO 2and greater decreases in the OI and the alveolar-arterial oxygen gradient than the control group (p<0.001 for all parameters). Significantly more patients had at least a partial response to the initial administration of study drug in the nitric oxide group (66%) than the control group (26%, p<0.001). Of the 125 infants who did not respond to 20 ppm nitric oxide control, similar percentages of NO-treated (18%) and control (20%) patients had at least a partial response to 80 ppm nitric oxide gas for inhalation or control drug, suggesting a lack of additional benefit for the higher dose of nitric oxide. No infant had study drug discontinued for toxicity. Inhaled nitric oxide gas had no detectable effect on mortality. The adverse events collected in the NINOS trial occurred at similar incidence rates in both treatment groups [see Adverse Reactions (6.1)] . Follow-up exams were performed at 18-24 months for the infants enrolled in this trial. In the infants with available follow-up, the two treatment groups were similar with respect to their mental, motor, audiologic, or neurologic evaluations.

CINRGI Study

This study was a double-blind, randomized, placebo-controlled, multi-center trial of 186 term and near-term neonates with pulmonary hypertension and hypoxic respiratory failure. The primary objective of the study was to determine whether nitric oxide gas would reduce the receipt of ECMO in these patients. Hypoxic respiratory failure was caused by MAS (35%), idiopathic PPHN (30%), pneumonia/sepsis (24%), or RDS (8%). Patients with a mean PaO 2of 54 mmHg and a mean OI of 44 cm H 2O / mmHg were randomly assigned to receive either 20 ppm nitric oxide gas (n=97) or nitrogen gas (placebo; n=89) in addition to their ventilatory support. Patients who exhibited a PaO 2>60 mmHg and a pH < 7.55 were weaned to 5 ppm nitric oxide gas or placebo. The primary results from the CINRGI study are presented in Table 2.

Table 2: Summary of Clinical Results from Persistent Pulmonary Hypertension of the Newborn Study Placebo Nitric oxide gas P value - * Extracorporeal membrane oxygenation

- † ECMO was the primary end point of this study

ECMO *,† 51/89 (57%) 30/97 (31%) <0.001 Death 5/89 (6%) 3/97 (3%) 0.48 Significantly fewer neonates in the nitric oxide gas group required ECMO compared to the control group (31% vs. 57%, p<0.001). While the number of deaths were similar in both groups (Nitric oxide gas, 3%; placebo, 6%), the combined incidence of death and/or receipt of ECMO was decreased in the nitric oxide gas group (33% vs. 58%, p<0.001).

In addition, the nitric oxide gas group had significantly improved oxygenation as measured by PaO 2, OI, and alveolar-arterial gradient (p<0.001 for all parameters). Of the 97 patients treated with nitric oxide gas, 2 (2%) were withdrawn from study drug due to methemoglobin levels >4%. The frequency and number of adverse events reported were similar in the two study groups [see Adverse Reactions (6.1)].

In clinical trials, reduction in the need for ECMO has not been demonstrated with the use of inhaled nitric oxide in neonates with congenital diaphragmatic hernia (CDH).

14.2 Ineffective in Adult Respiratory Distress Syndrome (ARDS)

In a randomized, double-blind, parallel, multicenter study, 385 patients with adult respiratory distress syndrome (ARDS) associated with pneumonia (46%), surgery (33%), multiple trauma (26%), aspiration (23%), pulmonary contusion (18%), and other causes, with PaO 2/FiO 2<250 mmHg despite optimal oxygenation and ventilation, received placebo (n=193) or nitric oxide gas (n=192), 5 ppm, for 4 hours to 28 days or until weaned because of improvements in oxygenation. Despite acute improvements in oxygenation, there was no effect of nitric oxide gas on the primary endpoint of days alive and off ventilator support. These results were consistent with outcome data from a smaller dose ranging study of nitric oxide (1.25 to 80 ppm). GENOSYL (nitric oxide) for inhalation is not indicated for use in ARDS.

14.3 Ineffective in Prevention of Bronchopulmonary Dysplasia (BPD)

The safety and efficacy of nitric oxide gas for the prevention of chronic lung disease [bronchopulmonary dysplasia (BPD)] in neonates ≤ 34 weeks gestational age requiring respiratory support has been studied in four large previously conducted multicenter, double-blind, placebo-controlled clinical trials in a total of 2,600 preterm infants. Of these, 1,290 received placebo, and 1,310 received inhaled nitric oxide at doses ranging from 5-20 ppm, for treatment periods of 7-24 days duration. The primary endpoint for these studies was alive and without BPD at 36 weeks postmenstrual age (PMA). The need for supplemental oxygen at 36 weeks PMA served as a surrogate endpoint for the presence of BPD. Overall, efficacy for the prevention of bronchopulmonary dysplasia in preterm infants was not established. There were no meaningful differences between treatment groups with regard to overall deaths, methemoglobin levels, or adverse events commonly observed in premature infants, including intraventricular hemorrhage, patent ductus arteriosus, pulmonary hemorrhage, and retinopathy of prematurity.

The use of GENOSYL (nitric oxide) for prevention of BPD in preterm neonates ≤34 weeks gestational age is not recommended.

-

16 HOW SUPPLIED/STORAGE AND HANDLING

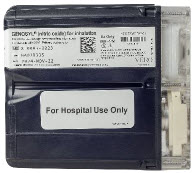

GENOSYL Delivery System Cassettes produce at least 216 liters of 800 ppm nitric oxide gas (at standard temperature and pressure, STP) (NDC: 72385-002-01).

GENOSYL Delivery System External Transport Cassettes produce at least 73 liters of 800 ppm nitric oxide gas (at standard temperature and pressure, STP) (NDC: 72385-003-01).

Store at 20°C to 25°C (68°F to 77°F) with excursions permitted between 15°C and 30°C (59°F and 86°F) [see USP Controlled Room Temperature].

The GENOSYL Delivery System must be used with antioxidant Cartridges not older than 12 months from the manufacturing date.

-

INSTRUCTIONS FOR USE

VĒRO

BIOTECHGENOSYL ®

DELIVERY SYSTEM

FOR DELIVERY OF

GENOSYL ®

(NITRIC OXIDE)

GAS FOR INHALATIONOPERATOR'S MANUAL

Technical Support: 877.337.4118

Company Confidential

Part No. 602502 Rev. IDO NOT COPY

VERO Biotech Inc.

387 Nerem Street NW, Suite 125

Atlanta, GA 30313 USAWARNINGS, CAUTIONS, AND NOTES

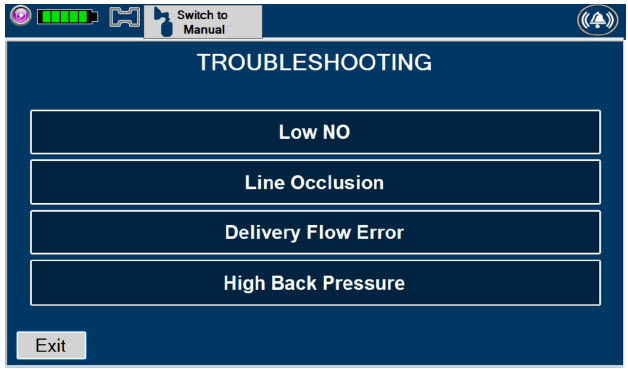

Please read all Warnings and Cautions in this Operator's Manual prior to using the GENOSYL DS.

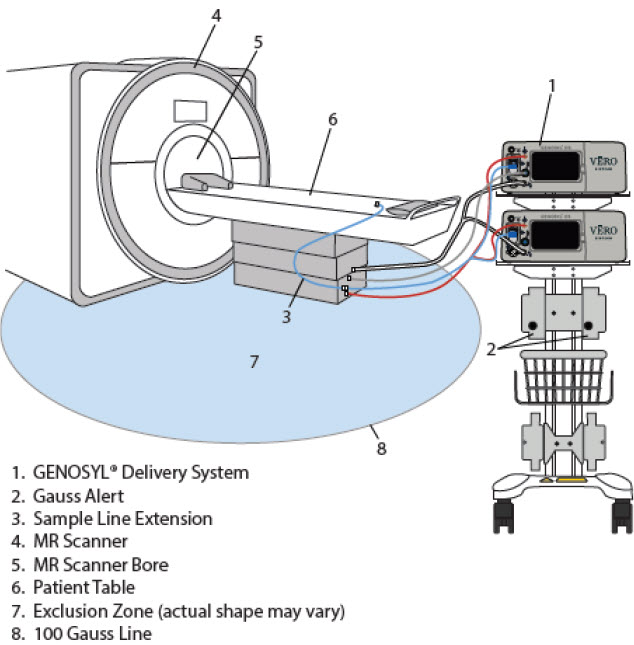

MR Conditional Safety Information

The GENOSYL DS may be safely used in the MR environment under the following conditions. Failure to follow these conditions may result in injury.

- Maximum static magnetic field of 100 Gauss (0.01mT)

- Device remains outside the scanner bore

- Preparation protocols described in the Warnings section titled "Use in the MR Environment" must be followed before MR procedure

Image Artifacts:

When the GENOSYL DS is battery powered, no image artifacts are expected. When powered using a wall outlet, minor noise is expected.

Throughout this Operator's Manual, warnings, cautions, and notes will be displayed in the following manner.

WARNING The warning box will alert the user to possible injury, death, or serious adverse reactions associated with the use or misuse of the device. CAUTION The caution box will alert the user about proper use of the equipment and any conditions that could result in equipment damage or failure. The user should read and adhere to all warnings and cautions. NOTE The note box provides information, clarification, or supplemental information to assist and educate the user on the use of the equipment. A complete list of Warnings and Cautions for the GENOSYL DS are shown below. Where appropriate, some of these will also be shown throughout this manual.

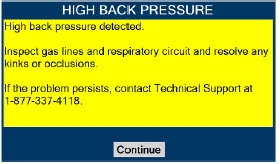

WARNINGS Please consult the package insert for a complete list of contraindications. Alarms - ALWAYS acknowledge and follow information provided from alarms. An alarm indicates an abnormal condition, and ignoring alarms can result in possible injury, death, or serious adverse reactions.

- ALWAYS use clinical judgement when setting upper or lower alarm limits. Failure to do so could result in possible injury or death.

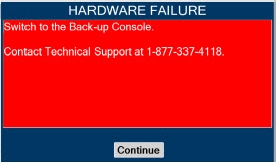

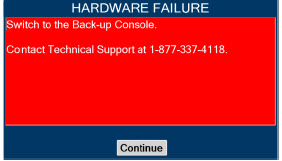

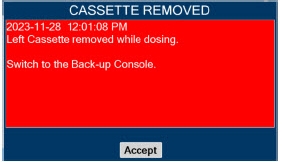

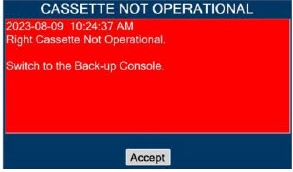

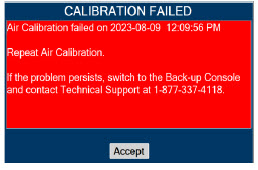

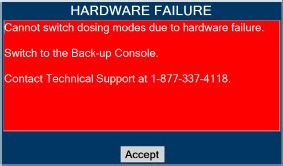

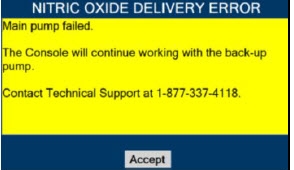

Consoles - ALWAYS have a second Console present and properly connected when a Dosing Console is connected to the patient. If the Dosing Console malfunctions, switch to the Back-up Console. If the Back-up Console is not available or properly connected, this may result in patient injury or death.

- DO NOT clean the GENOSYL DS with the power connected and the System turned ON, as this may lead to injury (e.g., shock). Unplug AC/DC power supply external to the System prior to cleaning.

- NEVER modify the equipment. Modifications of the equipment may result in malfunction, which may result in a fire, shock, injury, or death.

- NEVER turn the rear power switch OFF until the System has gone through a controlled shutdown or instructed by VERO Technical Support. Turning the rear power switch OFF prematurely (e.g., while it is still in use) will immediately shut down the device. This may result in interruption in NO delivery to the patient, which may cause injury or death.

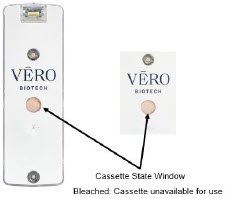

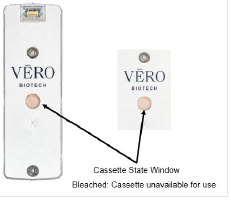

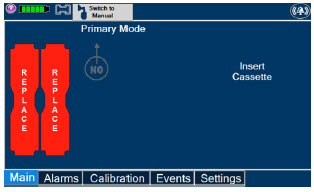

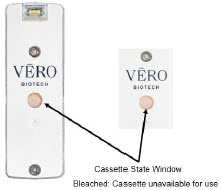

Cassette - DO NOT use the Cassette if the Cassette State Window is not blue. A Cassette State Window that is any color other than blue may affect the Cassette's ability to provide the correct NO dosage to the patient, which may cause injury or death.

- DO NOT use a Cassette that is beyond its expiration date. Using an expired Cassette may affect the Cassette's ability to provide the correct NO dosage to the patient, which may cause injury or death.

- MAKE SURE the System stabilizes to the prescribed concentration (ppm) of NO prior to leaving the Console unattended. Failure to do so could result in under delivery of the target NO, leading to injury or harm.

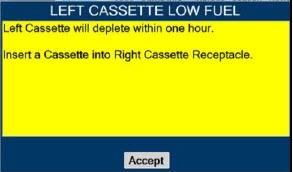

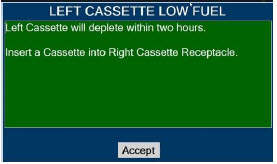

- ALWAYS replace a Cassette once depleted. A depleted Cassette will interrupt patient dosing and can lead to underdosing and/or injury to the patient.

- ALWAYS follow Cassette inspection instructions prior to Cassette insertion. Not inspecting the Cassette prior to insertion may lead to using a faulty Cassette, resulting in injury.

Use in the MR Environment - The GENOSYL DS is classified as MR Conditional with MR scanners of 1.5 or 3.0 Tesla strength ONLY in areas where the field strength is less than 100 gauss.

- ALWAYS operate at a fringe field of less than 100 gauss. This device contains ferromagnetic components and may experience strong attraction close to the magnet.

- DO NOT exceed 100 gauss; System operation may be impacted. Confirm Cart caster lock function. Optionally connect tether.

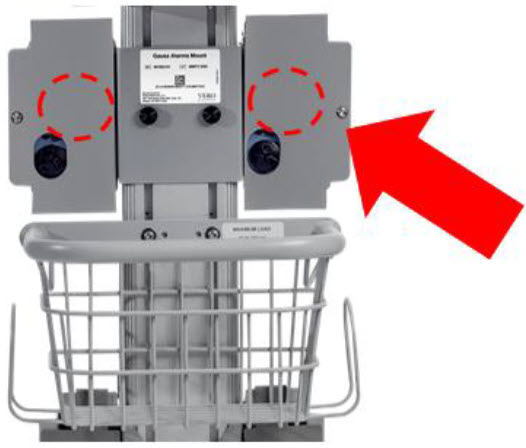

- NEVER use the GENOSYL DS in the MR scanner room without gauss alarms installed.

- ALWAYS verify at least one gauss alarm is functioning properly prior to use in the MR environment.

- DO NOT use the GENOSYL DS in the MR environment if neither gauss alarm is functional.

- ALWAYS move System away from the MR scanner if the gauss alarm sounds. The gauss alarm will sound if the System is too close to the MR scanner. Move System away from the MR scanner until the gauss alarm stops sounding.

- ALWAYS verify that the GENOSYL DS Cart casters are locked after positioning the System in the MR scanner room.

- ALWAYS verify that the GENOSYL DS is securely attached to the Cart.

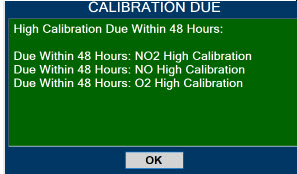

- ALWAYS arrange power cord, MR patient gas sample line, and NO delivery line to avoid entanglement, strangulation and/or a trip hazard.

- DO NOT use the GENOSYL DS in the MR environment if the Cart moves when the brake caster locks are engaged.

- NEVER perform NO or NO 2calibration within the MR scanner room. Calibration equipment is a potential projectile hazard.

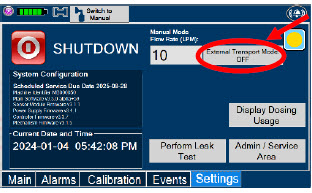

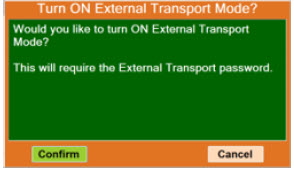

Transport - ALWAYS ensure the GENOSYL DS Dosing and Back-up Consoles are securely affixed to the External Transport Mounts when the System will be used in a transport vehicle.

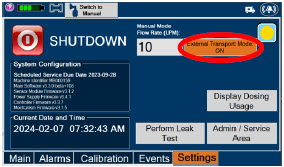

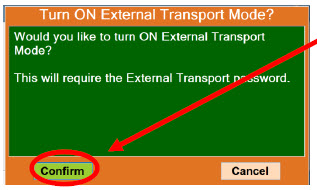

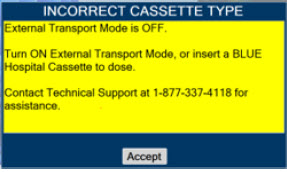

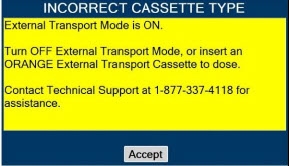

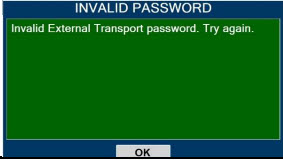

- ALWAYS ensure Consoles are placed into External Transport Mode before inserting a Cassette for external transport outside of the hospital.

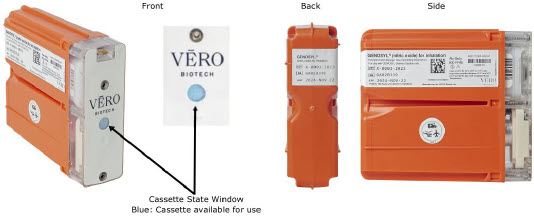

- ONLY use External Transport Cassettes, identified by orange color and transport sticker, in external transport outside of the hospital.

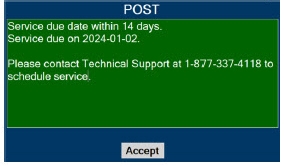

- ALWAYS ensure the External Transport Mounts are secured during patient transport, per hospital protocols.

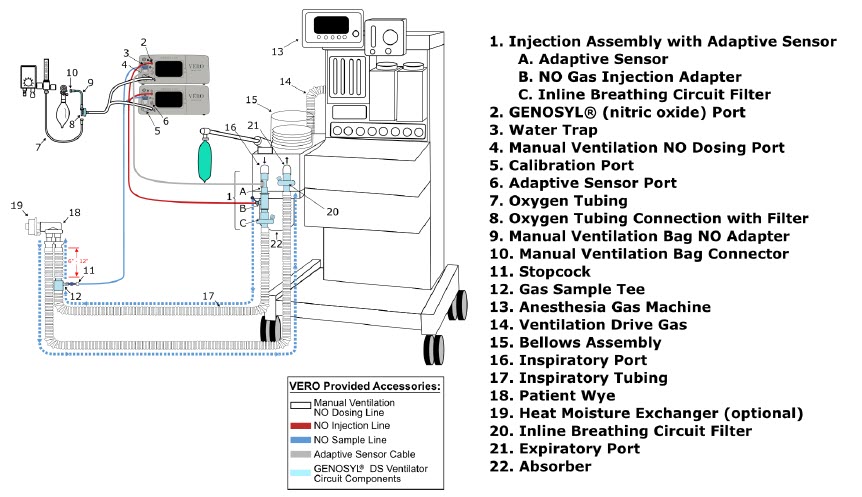

Use with Anesthesia Gas Machines - ALWAYS use the Anesthesia Gas Machine (AGM) in accordance with the manufacturer's instructions.

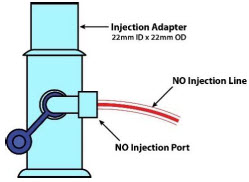

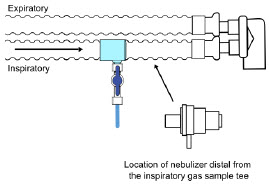

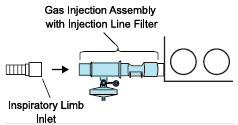

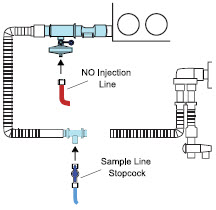

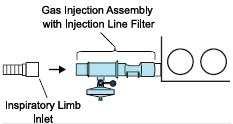

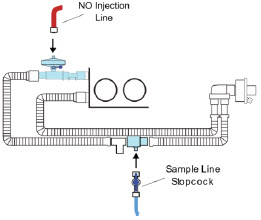

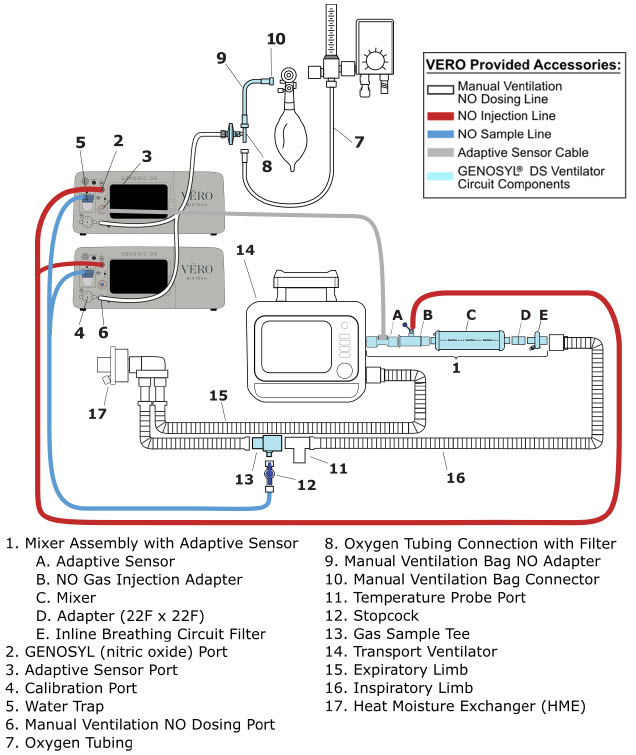

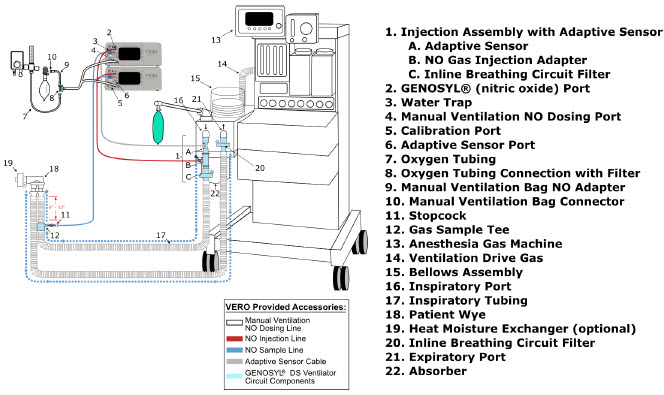

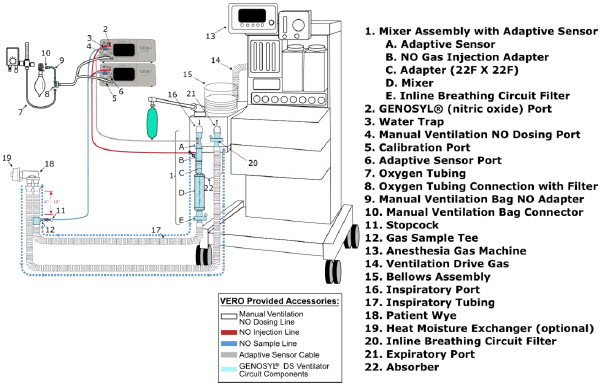

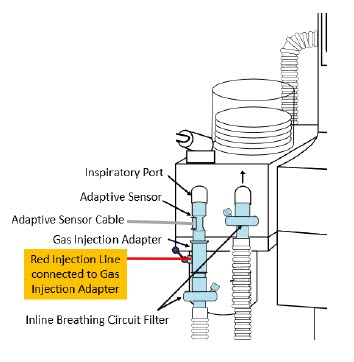

- The flow out of the anesthesia gas machine via the INSPIRATORY breathing circuit limb must pass through the GENOSYL DS Gas Injection Assembly.

- The GENOSYL DS injects and samples gas from the patient respiratory circuit which may affect the triggering sensitivity of the anesthesia gas machine (AGM). ALWAYS ensure the trigger sensitivity of the AGM is checked after connecting the GENOSYL DS to the breathing circuit and starting iNO delivery or when the dose is changed and adjust trigger sensitivity as necessary. Failure to do so may lead to AGM auto cycling or apnea alarm.

- ALWAYS ensure the patient disconnect and high–pressure alarms are used with the AGM.

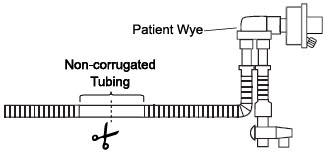

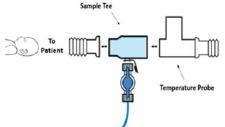

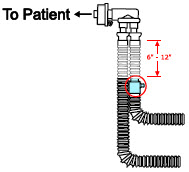

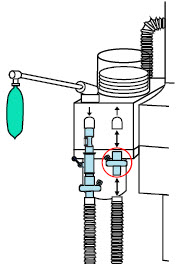

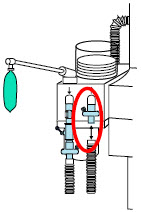

- Ensure the Injection Assembly and the Gas Sample Tee are BOTH inserted on the inspiratory limb of the circuit.

Connections - ALWAYS follow pre-use setup instructions for the routing and connections of tubing to avoid patient strangulation.

- MAKE SURE the System has all tubing connected as described in the instructions. Not connecting all tubing may result in inaccurate dosage and harm the patient.

- NEVER touch the electrical connectors of the System or its accessories, and the patient simultaneously. If the user touches another device with a ground-fault failure and simultaneously touches the GENOSYL DS, this can result in injury (e.g., shock) should a grounding failure be present.

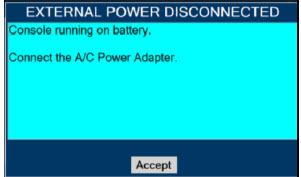

Battery - ONLY properly trained personnel should replace the battery. Incorrectly replacing the battery may result in a hazard such as excessive temperatures, fire, or explosion.

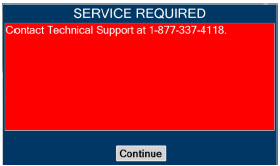

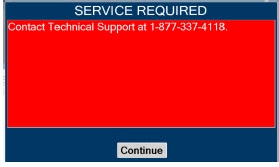

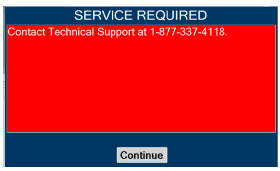

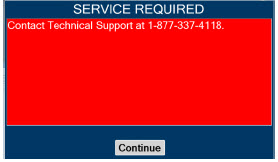

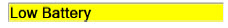

- MAKE SURE the GENOSYL DS is connected to AC wall power to charge the battery a minimum of once every 3 months to maintain a minimum battery charge. Failure to recharge the Console battery for extended timeframes may result in full discharge of the battery. If a Battery Error message occurs during startup of the System, contact Technical Support at 877-337-4118 for assistance.

User - ONLY intended users who are experienced in the use of this System should use this device. US federal law restricts device use to licensed medical professionals. If device is used by unintended users, device can be misused and lead to injury or death.

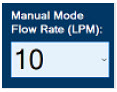

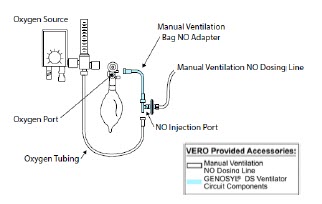

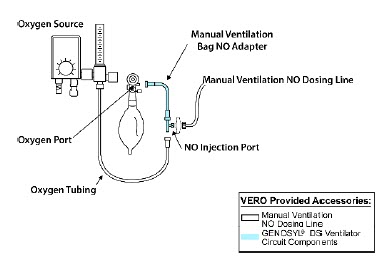

Alternative Means of Ventilation - ALWAYS ensure that the manual flow displayed on the Console matches the flow set into the resuscitation bag. Incorrect flow settings may result in an incorrect estimation of NO delivery. If the flow into the manual equipment is too low, there is risk of overdosing the patient with NO.

- ALWAYS squeeze the bag several times, after starting fresh gas flow, to empty residual gas in the bag prior to using the System to ventilate a patient. Failure to do so could result in higher NO 2levels being delivered to the patient.

- ALWAYS use the smallest bag adequate to deliver the desired tidal volume. Failure to do so could result in higher NO 2levels being delivered to the patient.

Patient Monitoring - ALWAYS constantly monitor the patient. System malfunctions can occur if device and patient are not monitored and can result in injury or death. Careful monitoring is required by care personnel whenever the System is used on a patient. The use of an alarm and a monitoring system does not give an absolute assurance of warning for every malfunction that may occur. Certain alarms may require immediate response.

Use with Breathing Devices - ONLY use a manual resuscitation bag with the GENOSYL DS for a short time (e.g., less than one hour) when on battery only. Otherwise, the System may shut off and may result in injury or death.

- The GENOSYL DS injects and samples gas from the patient respiratory circuit which may affect the triggering sensitivity of the ventilator. ALWAYS ensure the trigger sensitivity of the ventilator is checked after connecting the GENOSYL DS to the breathing circuit or when the dose is changed and adjust trigger sensitivity as necessary. Failure to do so may lead to ventilator auto cycling or apnea alarm.

- ALWAYS ensure the patient disconnect and high-pressure alarms are used with the ventilator.

- ONLY use the GENOSYL DS with Bio-Med Crossvent 2+ with Constant Flow ON. Not doing so may lead to elevated NO2 levels or dose variability.

Set-up - ONLY VERO Biotech authorized equipment technicians are to perform the initial System set-up prior to initial use. Failure to use an authorized equipment technician can result in a patient or user injury.

- ONLY store the GENOSYL DS as outlined in the storage instructions. Not storing the device in alignment with its storage instructions can cause the device to be unsafe and lead to injury or death.

- AVOID using the GENOSYL DS adjacent to or stacked with other equipment, as it may result in improper operation. If such use is necessary, this equipment and the other equipment should be observed to verify that they are operating normally.

- DO NOT use accessories or cables other than those specified or provided by the manufacturer of this equipment, as this may result in increased electromagnetic emissions or decreased electromagnetic immunity of this equipment and result in improper operation.

- DO NOT place portable RF communications equipment (including peripherals such as antenna cables and external antennas) closer than 30cm (12 inches) to any part of the GENOSYL DS, including cables specified. Otherwise, degradation of the performance of this equipment could occur, resulting in injury.

- Only connect to a power outlet with protective earth. Failure to connect to an outlet with protective earth may result in an electrical shock.

Troubleshooting - ALWAYS ensure patient safety before troubleshooting (such as an activated alarm) or replacing a problematic item. Not monitoring the patient prior to attending to an alarm can result in injury or death.

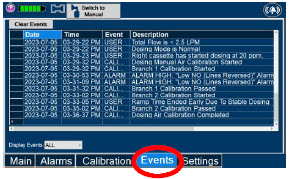

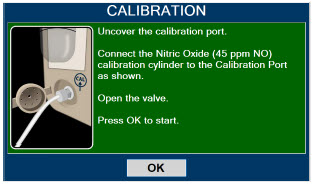

Calibration - ONLY use the calibration gas pressure regulators supplied by the manufacturer. Pressure regulators not supplied by the manufacturer may damage the sensors and may lead to patient injury.

- ALWAYS verify the correct NIST traceable calibration gas is being used and confirm the expiration date of the calibration gas prior to performing calibration. The use of incorrect or expired gas may result in inaccurate sensor readings and can lead to patient injury.

Cleaning and Maintenance - NEVER submerge the GENOSYL DS, Cassettes, or non-disposable Adaptive Sensor Cable. Submerging in liquids will damage the System and could cause electrical shorts which may result in injury or death.

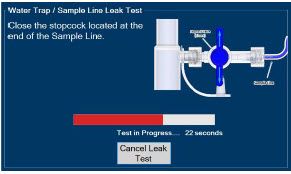

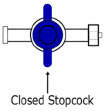

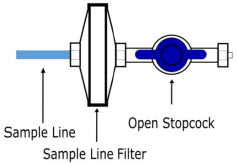

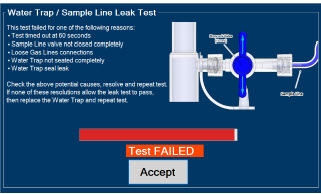

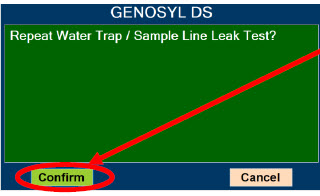

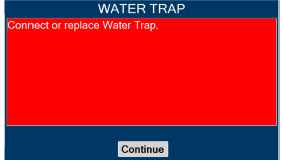

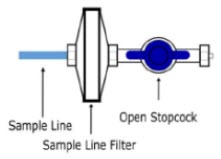

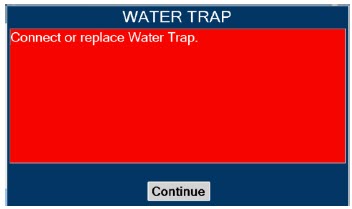

Water Trap - ALWAYS empty Water Trap when prompted by the System, and when the trap is more than half full. Allowing the Water Trap to completely fill will occlude the Sample Line which will interrupt patient gas NO, NO 2, and O 2concentration monitoring. Failure to monitor the patient gas NO, NO 2, and O 2concentrations may result in patient injury.

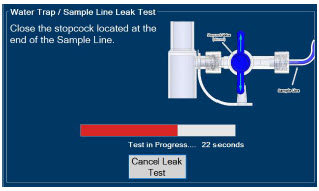

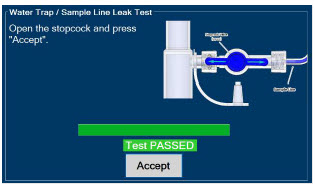

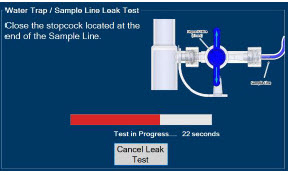

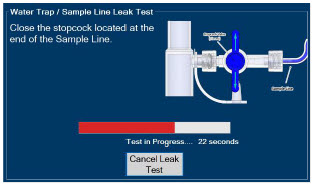

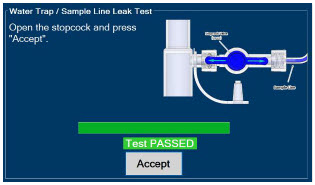

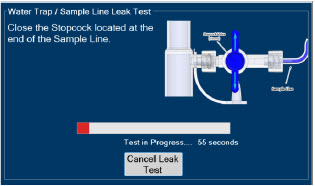

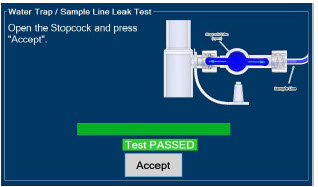

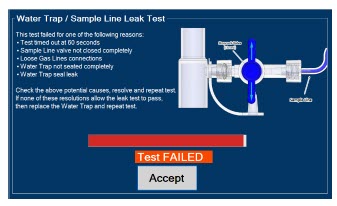

- ALWAYS conduct Water Trap / Sample Line Leak Test every time you empty and replace the Water Trap, as failure to do so may lead to an incorrect NO reading, which can result in injury or death.

- ALWAYS use a Water Trap supplied by the manufacturer. Using an incorrect Water Trap could result in non-functioning or inaccurate sensor readings.

Use Outside of Product Labeling - ALWAYS use the GENOSYL DS in accordance with the indications, usage, contraindications, warnings, and precautions described in the GENOSYL prescribing information and labeling. Refer to latest approved prescribing information and labeling prior to use.

- The approved patient population for the GENOSYL DS as specified in the drug labeling for GENOSYL (nitric oxide) for inhalation, is limited to neonates. The GENOSYL DS is not intended to be used in other patient populations.

- ONLY use the GENOSYL DS, its parts, and accessories as instructed. Using non-specified components may result in product malfunction, injury, or death

- ONLY trained personnel should operate the GENOSYL DS. Failure to do so can result in injury or death.

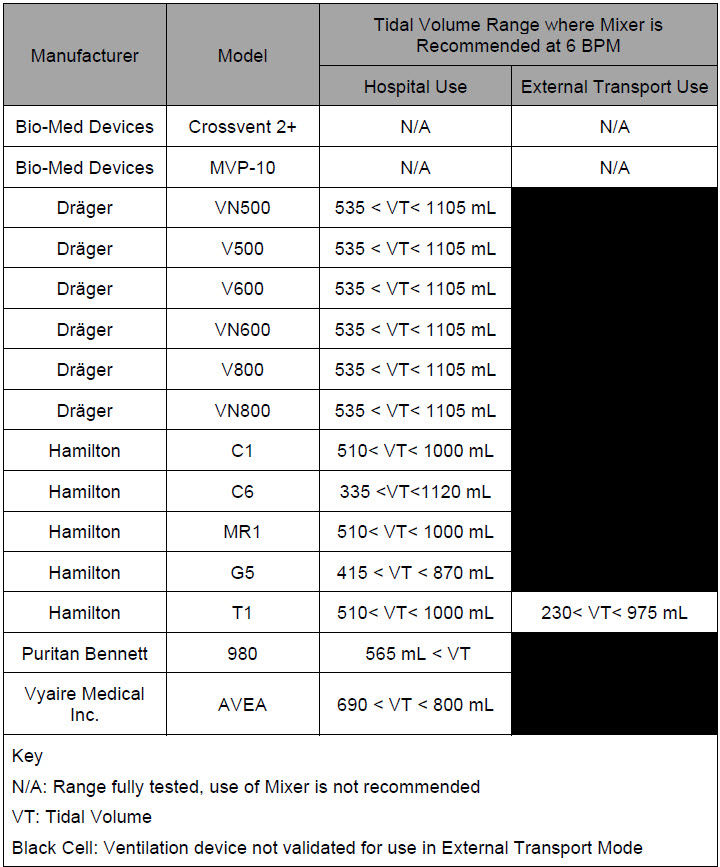

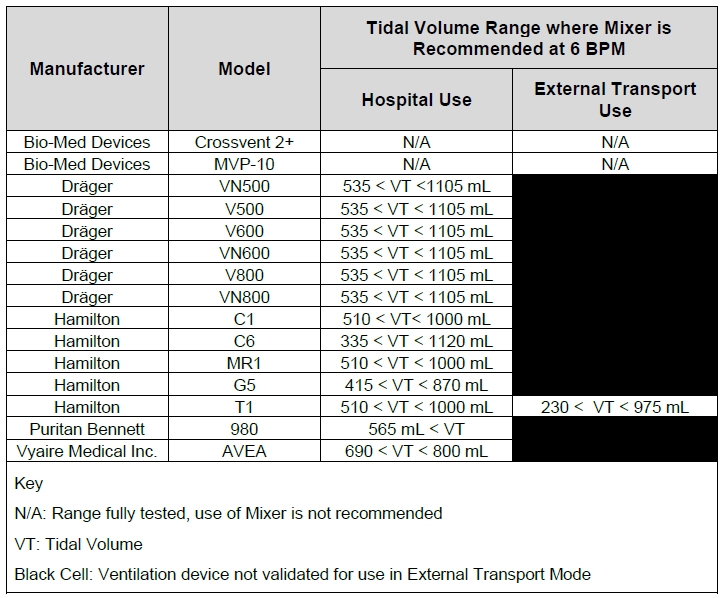

- ONLY mechanical ventilators validated with the GENOSYL DS should be used. Not using a validated ventilator system can result in injury or harm.

CAUTIONS Supplied Instructions - ALWAYS refer to the instructions supplied with all equipment to be used in conjunction with the GENOSYL DS for their intended uses, contraindications, and potential complications. Misuse of the device or its components may damage the device.

Cassette - DO NOT remove Cassette from packaging until ready to use. External packaging is designed to protect the Cassette from damage and/or contamination.

- User should always have a secondary Cassette inserted in the Dosing Console and preheated in order for auto transition to occur. User should replace depleted Cassette as soon as possible after ejection.

Consoles - ALWAYS operate the Console on a level surface to avoid potential interruption to nitric oxide (NO) delivery.

- ONLY use recommended cleaning agents or a damp cloth to clean the Console and limit use of liquids around Console. Excess water can permanently damage the device.

- ONLY use the GENOSYL DS with the power cord supplied by the manufacturer. Use of a generic power cord may cause output voltage instability leading to a touch screen failure.

- ALWAYS ensure the power cord is firmly seated into the power supply and the wall outlet. A loose connection can result in damage to the device or faulty operation.

- Prolonged use in dry environments without humidification will damage the gas sensors. Supplemental humidification providing greater than 20% relative humidity (RH) in the patient circuit is recommended.

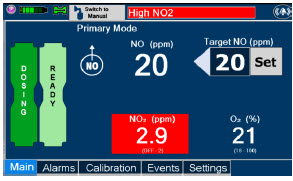

Use with Breathing Devices - When using spontaneous breathing modeson respiratory device, NO 2levels may exceed 3.0 ppm NO when dosing ≥ 57 ppm NO into 100% FiO 2and maximum bias flow, resulting in nitric oxide delivery interruption. Once sample value of NO 2is below 3.0 ppm, the Console will auto resume delivery of NO at set dose. Refer to Section 12.1.5 Table 13for additional information.

- When using non-spontaneous breathing modeson respiratory device NO 2levels may exceed 3.0 ppm when dosing ≥ 63 ppm NO into 100% FiO 2and maximum bias flow, resulting in nitric oxide delivery interruption. Once sample value of NO 2is below 3.0 ppm, the Console will auto resume delivery of NO at set dose. Refer to Section 12.1.5 Table 13for additional information.

Use with Anesthesia Gas Machines - The Adaptive Sensor is recommended for use with anesthesia gas machines (AGMs). When using an AGM without the Adaptive Sensor, transient dose excursions outside of the set NO dose may occur during Cassette transition, and changes in breathing circuit flow may cause fluctuations in measured levels of NO and NO 2when using the manual ventilation bag integrated with the AGM.

- When using anesthesia gas machines, NO 2levels may exceed 3.0 ppm when dosing ≥ 58 ppm NO into 100% FiO 2, resulting in nitric oxide delivery interruption. Once sample value of NO 2is below 3.0 ppm, the Console will auto resume delivery of NO at set dose.

- DO NOT use in environments with <20% relative humidity (RH) in the absence of supplemental humidification. Prolonged use in dry environments without humidification will damage the gas sensors. GENOSYL DS was validated with listed AGMs using a Heat Moisture Exchanger (HME) and was not tested with heated humidification connected to the respiratory circuit.

- Rebreathing validation testing was performed with semi-closed breathing systems. Non-rebreathing validation testing was perfumed with semi-open breathing systems. The GENOSYL DS has not been evaluated with fully open or fully closed anesthesia breathing systems.

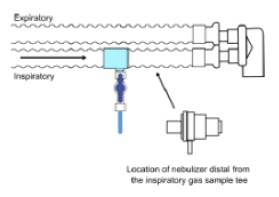

Gas Sampling During Aerosol Delivery - Pneumatic Nebulizers will dilute the delivered nitric oxide dose.

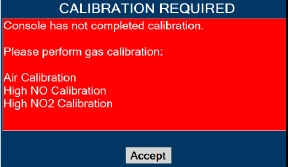

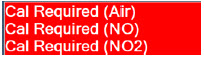

Calibration - ALWAYS perform a full-scale calibration of the GENOSYL DS when prompted by the System prior to use.

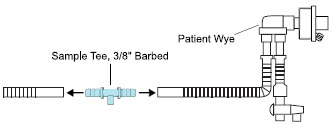

- ALWAYS confirm the correct flow direction of the installed one-way check valve in the sampling tee to avoid over pressurization of the sample system and damage to the device.

Cleaning and Maintenance - ALWAYS follow maintenance instructions in this manual for your safety and to prevent damage to the System.

- ALWAYS power down the GENOSYL DS Console when not in use.

- DO NOT sterilize (e.g., autoclave, gas sterilize) any of the components of the System, as this may compromise performance.

- DO NOT use harsh cleaning agents. Doing so may impair the structural integrity and/or function of the device.

- DO NOT touch or rub the display screen with abrasive cleaning compounds, as they may scratch and damage the screens.

- ALWAYS ensure the System is completely dry after cleaning before powering it ON. Failure to do so could result in equipment damage.

Switching OFF the System - NEVER turn the rear power switch OFF until the System has gone through a controlled shutdown or instructed by VERO Technical Support. Turning the rear power switch OFF prematurely (e.g., while it is still in use) will immediately shut down the device and may cause improper operation upon restart.

Cart - DO NOT stand or sit on the Cart. Standing or sitting on the Cart can damage the device.

- ALWAYS push or pull the Cart using the handle only. NOT doing so may result in damage to the device.

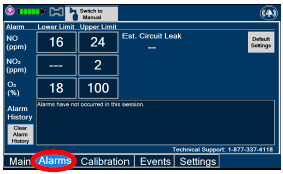

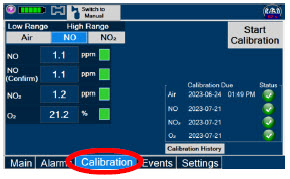

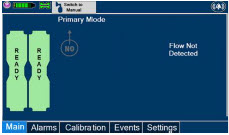

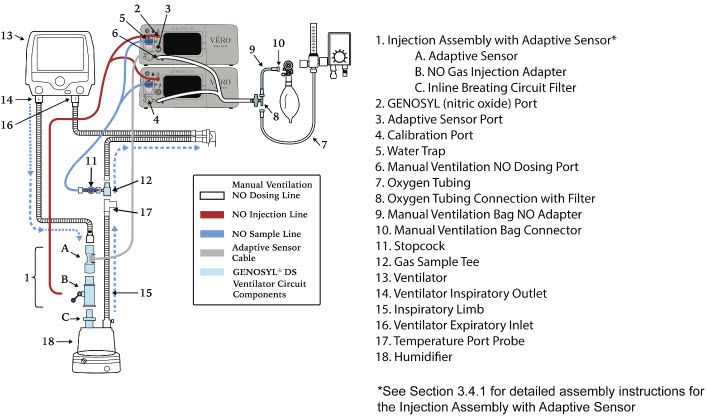

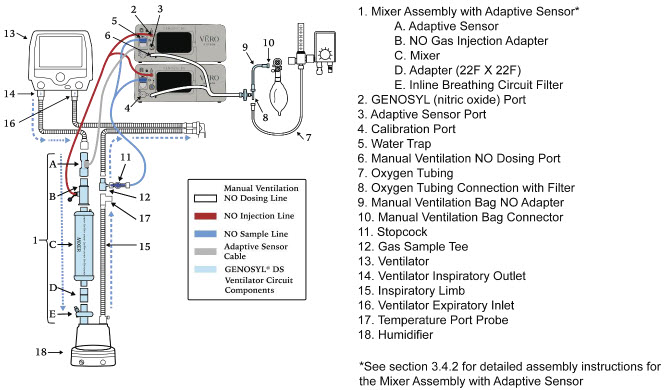

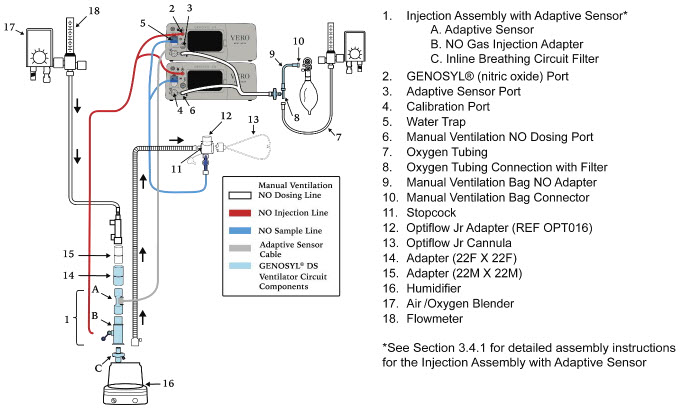

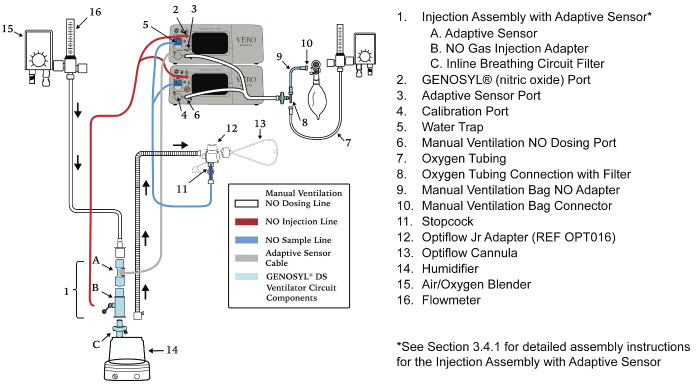

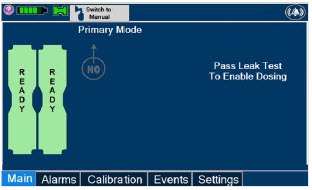

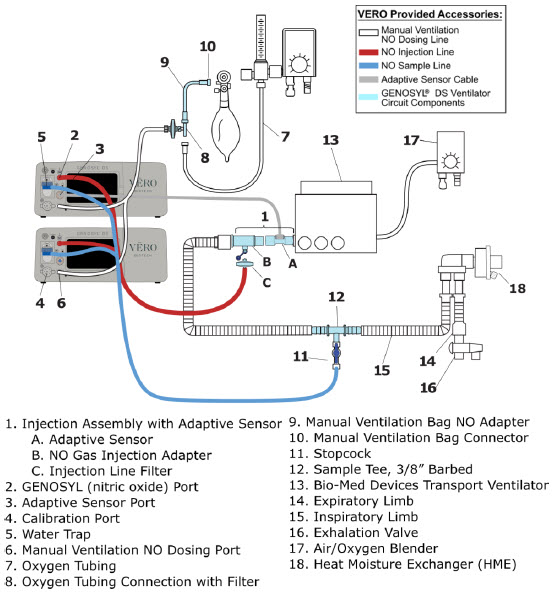

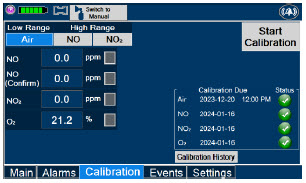

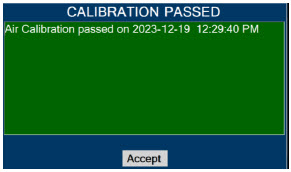

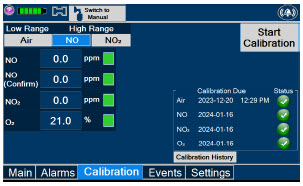

TABLE OF CONTENTS WARNINGS, CAUTIONS, AND NOTES 3 TABLE OF CONTENTS 12 LIST OF TABLES 16 LIST OF FIGURES 17 ABBREVIATIONS, TERMINOLOGY, AND DEFINITIONS 19 SYMBOLS 21 GENOSYL DS PARTS / COMPONENTS 23 1. GENERAL INFORMATION 32 1.1 User Responsibility 32 1.2 General Information and Indications for Use 33 1.3 Principles of Operation 34 1.4 Exposure of Healthcare Providers to NO and NO 2 38 2. SYSTEM OVERVIEW 42 2.1 Frequently Used Functions 42 2.2 GENOSYL DS Cart and Consoles 43 2.3 Cassette 49 2.4 GENOSYL DS Ventilator Circuit Components 51 2.5 Gas Lines (detailed explanation) 54 2.6 Console Dosing Modes of Operation 56 2.7 Display Screen 56 2.8 Display "Menu" Tab Navigation 57 2.9 Display Screen Operational Buttons 61 2.10 Display Screen – Cassette Status Indicators 63 2.11 Display Screen - Adaptive Sensor Status 67 2.12 Cassette Insertion into Console 68 2.13 Water Trap / Sample Line Leak Test 68 2.14 Console Shutdown - Cassette Status Indicator 69 2.15 Battery Charge Status Indicator 70 3. SYSTEM SET-UP AND CONNECTIONS 74 3.1 GENOSYL DS Set-Up and Mechanical Ventilator Circuit Schematic 74 3.2 Connections to Various Breathing Systems 74 3.2.1 Conventional Ventilators 75 3.2.2 Non-Invasive Gas Delivery Systems 79 3.3 GENOSYL DS Ventilator Circuit Assembly Pre-Check 81 3.4 Assembling GENOSYL DS Injection Assembly with Adaptive Sensor and GENOSYL DS Mixer Assembly with Adaptive Sensor 83 3.4.1 GENOSYL DS Injection Assembly with Adaptive Sensor 83 3.4.2 GENOSYL DS Mixer Assembly with Adaptive Sensor 84 3.5 GENOSYL DS Console Connections 86 3.5.1 GENOSYL DS Gas Line Connections 86 3.5.2 GENOSYL DS Sample Line Extension Connection 87 3.5.3 Sample Line Filter Connection 89 3.5.4 GENOSYL DS Adaptive Sensor Cable Connection 91 3.5.5 GENOSYL DS Respiratory Circuit Connections 91 3.6 Manual Ventilation (Bag) Connection 93 3.7 Mechanical Ventilator Circuit Connections 94 3.8 Gas Sampling During Aerosol Delivery 95 4. SYSTEM START UP 100 4.1 Console Start-Up 100 4.2 Cassette Insertion & Water Trap / Sample Line Leak Test 101 4.2.1 Water Trap / Sample Line Leak Test Troubleshooting 107 5. NITRIC OXIDE ADMINISTRATION 110 5.1 Nitric Oxide Dose Set-Up and Administration 110 5.1.1 Setting a Dose when using a Circuit withan Adaptive Sensor 110 5.1.2 Setting a Dose when using a Circuit withoutan Adaptive Sensor 112 5.2 Adjusting the Dose 113 5.3 Replacement of a Depleted Cassette 115 5.4 Manual Mode 116 5.4.1 Manual Ventilation Use (Bagging) 116 5.4.2 Preset Manual Dosing Mode Flow Rate (OPTIONAL) 119 5.4.3 Resuming Primary Dosing 119 5.5 Console Use as a Back-up 120 6. CONSOLE SHUTDOWN AND CASSETTE DISPOSAL 124 6.1 Console Shutdown 124 6.2 Cassette Disposal 128 7. USING THE SYSTEM IN THE MR SCANNER ROOM 132 7.1 Connection to the Ventilator Breathing Circuit 132 7.2 Transferring to and from the MR Scanner Room 133 8. EXTERNAL TRANSPORT 138 8.1 External Transport Set-Up and Ventilator Circuit Schematics 144 8.1.1 Securing a Console in a Transport Mount 144 8.1.2 Connection to an International Bio-Med External Transport Ventilator Circuit 145 8.1.3 Connection to a Conventional External Transport Ventilator 147 8.1.3.1 Connection to a Conventional External Transport Ventilator using an Injection Assembly with Adaptive Sensor 148 8.1.3.2 Transport Ventilator Circuit Set-Up and Connections using Mixer Assembly with Adaptive Sensor 151 8.2 Using the GENOSYL DS for External Transport 153 8.2.1 Switching External Transport Mode ON 153 8.2.2 Inserting an External Transport Cassette 155 8.2.3 Setting a Dose in External Transport Mode with an Adaptive Sensor 159 8.2.4 Setting a Dose in External Transport Mode without an Adaptive Sensor 161 8.2.5 Adjusting a Dose in External Transport Mode 163 8.2.6 Using Manual Dosing Mode while External Transport Mode is Enabled 164 8.2.7 Resuming Primary Dosing while in External Transport Mode 166 8.2.8 Console Shutdown while in External Transport Mode 167 8.2.9 Switching External Transport Mode OFF 171 9. USE WITH ANESTHESIA GAS MACHINES 174 8.1 Connection to a Dual Limb Anesthesia Circuit 176 8.2 Connection Instructions for the GENOSYL DS to an Anesthesia Gas Machine 177 10. ALARMS, ALERTS, AND TROUBLESHOOTING 184 10.1 Alarms, Alerts, and Troubleshooting 184 10.2 On-screen Troubleshooting Module 186 10.3 High Priority Alarms and Messages 189 10.4 Medium Priority Alarms and Messages 200 10.5 Low Priority Alarms and Messages 204 10.6 Informational Messages 205 10.7 GaussAlert™ Alarm 207 10.8 Troubleshooting 208 10.9 Leak Detection Tool 211 11. SYSTEM MAINTENANCE 216 11.1 Calibration 216 11.1.1 Air Calibration 217 11.1.2 NO Calibration 218 11.1.3 NO 2Calibration 220 11.2 Maintenance Schedule 222 11.3 Testing the GaussAlert™ Function 222 11.4 Water Trap Maintenance 224 11.4.1 Emptying the Water Trap 224 11.4.2 Water Trap Replacement 225 11.5 Battery 225 11.6 Cleaning 226 11.6.1 Enclosure, Connections, and Surfaces Other Than the Display 226 11.6.2 Display Screen 227 11.6.3 Cleaning the Gauss Alarms Mount 227 11.7.1 Cart / Console Storage 228 11.7.2 Cassette / Accessory Storage 228 12. MECHANICAL VENTILATION 232 12.1 Mechanical Ventilation 232 12.1.1 Oxygen Dilution 232 12.1.2 Minute Volume 234 12.1.3 Trigger Sensitivity 234 12.1.4 Maximum NO Delivery 234 12.1.5 Bias Flow and NO 2 234 12.2 Ventilator Compatibility 236 13 PRODUCT SPECIFICATIONS 246 13.1 System Performance 246 13.2 System Classification 246 13.3 Testing 246 13.4 Electrical 247 13.5 Power Supply 247 13.6 Battery 247 13.6.1 Battery Charge Status Indicator 248 13.17 Display 248 13.8 Mechanical 248 13.9 Environmental 249 13.10 GaussAlert™ Specifications 249 13.11 MR Signal-to-Noise Ratio and Artifact Dimension Analysis 249 13.12 EMI/EMC 250 KEY WORD INDEX 258 LIST OF TABLES Table 1: Conventional Ventilator Compatibility Test Ranges 76 Table 2: Non-Invasive Gas Delivery System Compatibility Test Ranges 79 Table 3: External Transport Ventilation Devices Compatibility Testing Ranges 140 Table 4: External Transport Equipment Specifications 143 Table 5: Anesthesia Gas Machine Validation Compatibility Test Ranges 175 Table 6: Anesthesia Gas Machine Tidal Volume Use Cases 176 Table 7: Alarm Icon Descriptions 184 Table 8: Alarm Characteristics 185 Table 9: Alarm Ranges, Defaults and Dose Interruption Condition 185 Table 10: Alarm conditions included in On-screen Troubleshooting Module 187 Table 11: Recommended Cleaning Agents 227 Table 12: Oxygen Dilution 233 Table 13: NO Dose at which NO 2exceeded 3ppm NO 2Threshold when dosing at 100% FiO 2and Maximum bias flow 235 Table 14: Details of Validated Systems 237 Table 15: Validated Compatibility with and without Inline Mixer 241 LIST OF FIGURES Figure 1: GENOSYL DS Console Front Panel 34 Figure 2: Cassette Output Range 35 Figure 3: Calculated Time to Hospital Cassette Depletion 36 Figure 4: Calculated Time to External Transport Cassette Depletion 36 Figure 5: GENOSYL DS Assembled Cart 44 Figure 6: MR Conditional GENOSYL DS Front View 45 Figure 7: MR Conditional GENOSYL DS Side View 46 Figure 8: Front View GENOSYL DS Console 47 Figure 9: Back View GENOSYL DS Console 48 Figure 10: Right Side View GENOSYL DS Console 48 Figure 11: Left Side View GENOSYL DS Console 48 Figure 12: GENOSYL Cassette 49 Figure 13: GENOSYL External Transport Cassette 50 Figure 14: GENOSYL DS Gas Lines 55 Figure 15: GENOSYL DS Display Screen 56 Figure 16: Water Trap/Sample Line Leak Test 69 Figure 17: Conventional Ventilator Circuit Set-Up and Connections using Injection Assembly with Adaptive Sensor to the GENOSYL DS and a Manual Bagging System 77 Figure 18: Conventional Ventilator Circuit Set-Up and Connection using the Mixer Assembly with Adaptive Sensor to the GENOSYL DS and a Manual Bagging System 78 Figure 19: Fisher and Paykel Optiflow Jr 2 Breathing Circuit 79 Figure 20: Fisher and Paykel Optiflow Breathing Circuit 80 Figure 21: GENOSYL DS Injection Assembly with Adaptive Sensor 83 Figure 22: GENOSYL DS Mixer Assembly with Adaptive Sensor 84 Figure 23: MR Scanner Room 134 Figure 24: Display Navigation in External Transport Mode 139 Figure 25: GENOSYL DS on External Transport Mount 141 Figure 26: External Transport Cassette 142 Figure 27: International Bio-Med Transport Ventilator Circuit Set-Up and Connections using Injection Assembly with Adaptive Sensor to the GENOSYL DS and a Manual Bagging System 145 Figure 28: Transport Ventilator Circuit Set-Up and Connections using Injection Assembly with Adaptive Sensor to the GENOSYL DS and a Manual Bagging System 148 Figure 29: Transport Ventilator Circuit Set-Up and Connections using Mixer Assembly with Adaptive Sensor to the GENOSYL DS and a Manual Bagging System 151 Figure 30: Anesthesia Gas Machine Circuit Set-up and Connection to the GENOSYL DS without Inline Mixer 177 Figure 31: Anesthesia Gas Machine Circuit Set-up and Connection to the GENOSYL DS with Inline Mixer 177 Figure 32: On-screen Troubleshooting Menu 187 Figure 33: Description of VERO On-screen Troubleshooting Module Navigation 188 Figure 34: Screen displayed if recommended actions cannot address alarm condition, or alarm condition is active and on-screen troubleshooting support is not available 189 Figure 35: "Alarms" tab display when a leak is suspected 212 Figure 36: GaussAlert™ Test 223 Figure 37: Cassette Output Range 236 ABBREVIATIONS, TERMINOLOGY, AND DEFINITIONS ABBREVIATION / TERMINOLOGY DEFINITION Adaptive Sensor Port Port on the front of the Console that the Adaptive Sensor Cable plugs into. AGM Anesthesia Gas Machine Back-up A situation whereby the Back-up Console and its Cassette is activated in the event of a failure of the Dosing Console. Back-up Console The secondary Console used as a "Back-up" system to administer nitric oxide when the Dosing Console cannot be used. BPM Breaths per minute Cassette The Cassette contains the material used to make nitric oxide and when inserted into the Console is available for dosing the patient. cmH 20 Centimeters of water / unit of pressure Display Electronic information panel located on the front of the Console. Dosing Console The Console that is actively dosing NO. DS Delivery System Gas Sample Port Port on the front of the Console at the Water Trap that measures NO, NO 2and O 2levels within the NO gas path prior to reaching the patient. GENOSYL Nitric oxide for inhalation Hz Hertz Keypad A Graphical User Interface function built into the Console display and used to enter the nitric oxide dose to be administered to the patient. L/min Liters per minute LPM Mixer Ventilator circuit accessory used to mix the ventilator gas with the gas supplied by the GENOSYL DS for specific ventilator and tidal volume use cases, per Section 12.2. MRI Magnetic Resonance Imaging MR Scanner Bore The MR scanner opening MR Exclusion Zone Area in the MR scanner room where the magnetic field is greater than 100 gauss MR Scanner The MR device for diagnostic imaging MR Scanner Room The room where the MR scanner is located mT Millitesla; Unit used to measure magnetic field NICU Neonatal Intensive Care Unit NO Nitric oxide NO Injection Port Port on the front of the Console that introduces the concentrated NO into the respiratory circuit. NO 2 Nitrogen dioxide N 2O 4 Dinitrogen tetroxide O 2 Oxygen OD Oxygen diameter PEEP Positive end-expiratory pressure ppm Parts er Million psi Pounds per square inch/ unit of pressure System The System (GENOSYL DS) consists of a Cart with two Consoles, Cassettes, and component parts used to set up the gas lines v Electrical Volts SYMBOLS Symbol Symbol Name Description

AC Indicates power input specification is alternating current (AC).

Adaptive Sensor Port Input port for Adaptive Sensor Cable

Atmospheric pressure limitation To indicate the acceptable upper and lower limits of atmospheric pressure for transport and storage.

Attention Indicates the need for the user to consult the instructions for use for important cautionary information such as warnings and precautions that cannot, for a variety of reasons, be presented on the medical device itself.

Batch Code Indicates the batch code so that the batch or lot can be identified.

Calibration Port Input port for calibration gas

Catalog or model number Indicates the catalog number so that the medical device can be identified.

Consult instructions for use Informs the user to consult the instructions for use.

Date of Manufacture Indicates the date when the medical device was manufactured.

Do not reuse Indicates a medical device that is intended for one use, or for use on a single patient during a single procedure.

External Transport Symbols Appears on External Transport Cassettes to indicate Cassette can be used during patient transfer in rescue vehicle, fixed wing, or helicopter.

Ingression Code for the level of ingression protection tested. The enclosure was tested to be drip proof.

Magnetic Resonance (MR) Conditional Indicates that the System has been demonstrated to pose no known hazards in a specified MRI environment with specified conditions of use.

Manual Ventilation Output port for GENOSYL to manual ventilation system

Manufacturer Indicates the manufacturer of the item.

NO Injection Output port for GENOSYL to patient circuit

Operating Instructions Refer to operating instructions for instructions for use, warnings, precautions, and other equipment information.

RF Interference Devices marked with this symbol may interfere with the Console.

Sample Gas Inlet Attachment point for Sample Line on Water Trap

Serial Number Indicates the serial number so that a specific medical device can be identified.

Storage humidity range Indicates the range of humidity to which the medical device can be safely exposed.

Storage temperature range Indicates the temperature limits to which the medical device can be safely exposed.

Unlock position Direction to push to open the Water Trap.

Use by Indicates the date after which the medical device is not to be used.

Water Trap Attachment Point Indicates the location where the Water Trap with Sample Port is to be attached. GENOSYL DS PARTS / COMPONENTS PART PART NAME

GENOSYL DS Cart

GENOSYL DS Console

(2 required per System)

MR Conditional GENOSYL DS System

Gauss Alarms Mount

(2 gauss alarms installed)

External Transport Mount

External Transport Mount with Quick Connect Plate

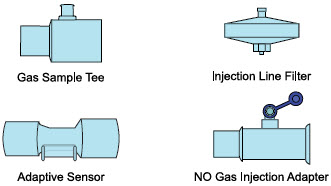

Adaptive Sensor Cable The following parts are required to set up the GENOSYL DS and deliver nitric oxide to the patient breathing circuit, using validated ventilators, ventilator circuits, and manual ventilation equipment.

PART PART NAME

GENOSYL Hospital Cassette

(may be referred to as Cassette or Hospital Cassette)

GENOSYL External Transport Cassette

(may be referred to as Cassette or External Transport Cassette)

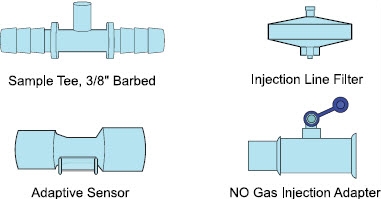

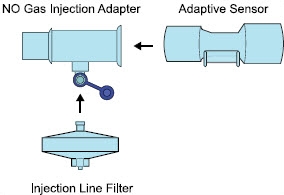

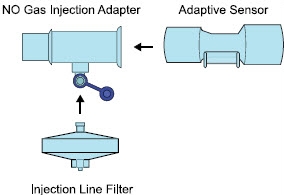

Adaptive Sensor

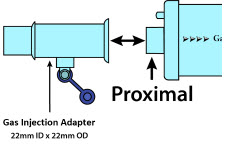

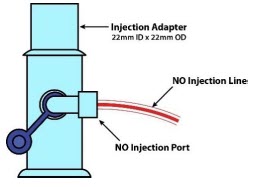

NO Gas Injection Adapter

22M/15F × 22F

Adapter

22F × 22F

Inline Breathing Circuit Filter .

GENOSYL DS Mixer

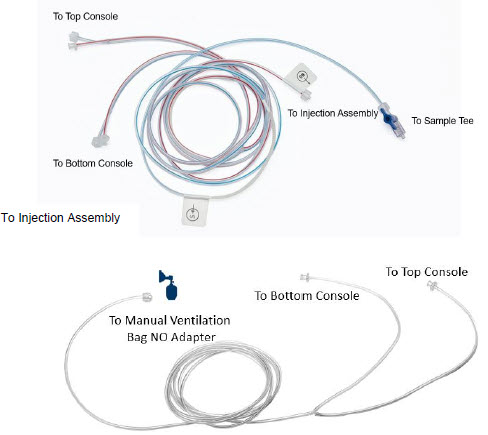

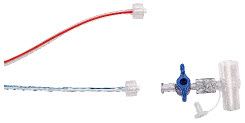

GENOSYL DS Gas Lines:

NO Injection Line (red)

Sample Line (blue)

Manual Ventilation Line (clear)

GENOSYL DS Sample Line Extension

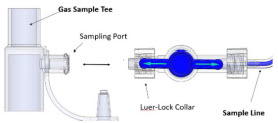

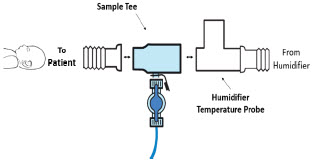

Neonatal Gas Sample Tee

Water Trap

22M 22F Elbow Adapter

Sample Line Filter

Sample Tee, 3/8" Barbed

Injection Line Filter

22M/15F × 22M/15F Adapter

15M × 4.5 Adapter

22M/15F × 15M Gas Sample Tee

22F × 15M Adapter Note: Physical appearances may vary slightly.

The following parts are required to deliver nitric oxide using a manual ventilation system.

PART PART NAME

GENOSYL DS Manual Ventilation Bag NO Adapter Note: Physical appearances may vary slightly.

The following parts are required for routine maintenance.

PART PART NAME

Calibration Gas - 45 ppm NO

Calibration Gas - 10 ppm NO 2

Calibration Regulator

Calibration Tee Tubing

Calibration Extension Tubing

Calibration Gas Carrying Case

Calibration Equipment Wrench

Calibration Regulator Teflon Washer Note: Physical appearances may vary slightly.

GENOSYL ®DS

SECTION 1

GENERAL INFORMATIONThe GENOSYL DS (Console) will perform as described in this Operator's Manual, accompanying inserts, and/or labels when assembled, operated, maintained, and repaired in accordance with the instructions provided. The Console must be set up as described in Section 3. If the Console does not perform as described in Section 3or during assembly, the parts are found to be broken, missing, contaminated, or visibly worn, they should be replaced immediately.

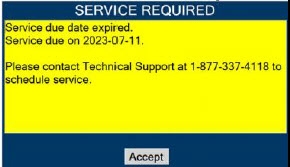

In the case of repair or replacement of the Console is required, a telephone service request should be made to Technical Support at 877-337-4118.The GENOSYL DS or any of its parts should not be serviced or repaired by anyone other than a VERO Biotech Technical Engineer or without written permission from VERO Biotech Technical Engineering Department.

Any malfunction resulting from faulty maintenance, improper repair, damage, alteration by anyone other than a VERO Biotech Technical Engineer, and/or improper use will be the sole responsibility of the User.

WARNING The GENOSYL DS must only be used in accordance with the approved indications, usage, contraindications, precautions, and warnings described in the GENOSYL DS labeling. Refer to the labeling prior to use. CAUTION U.S. Federal law restricts this device to sale by or on the order of a physician. Outside the U.S., check local laws for any restrictions that may apply. NOTES - Prior to using the GENOSYL DS, read through this Operator's Manual.

- Follow all instructions and obey the Warnings and Cautions.

- Keep this Operator's Manual available to readily answer questions.

- Read through all manufacturer Operator's Manuals for the ventilator, humidifier and any other accessory items used.

1.2 General Information and Indications for Use

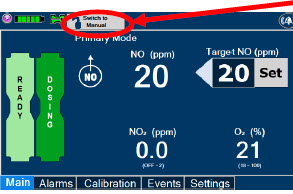

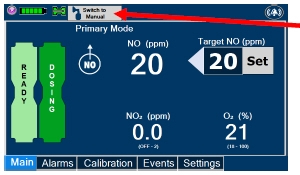

GENOSYL DS generates and delivers NO for inhalation at the point of use. The concentration of NO, as set by the user, is monitored, and adjusted to accurately dose the patient throughout an inspired breath. Only validated devices / components should be used with the GENOSYL DS.

The intended population for inhaled NO treatment is term and near-term neonates in neonatal intensive care units (NICUs). Refer to the GENOSYL (nitric oxide) for inhalation drug label for more detailed information.

The GENOSYL DS is intended for use in the hospital, 1.5 Tesla and 3.0 Tesla diagnostic imaging environments, during patient transfer via rescue vehicle, fixed wing aircraft, or helicopter, and the operating room in conjunction with validated anesthesia gas machines.

The GENOSYL DS is intended for use by healthcare professionals (HCPs) who are licensed and actively practicing pediatric and/or neonatal respiratory therapists (RTs), or HCPs in the operating room with the supervision of RTs in the United States. These users are required to set up, administer inhaled nitric oxide (iNO) and provide respiratory care (including initiation and maintenance of mechanical ventilators) in the critically ill neonatal population.

The GENOSYL DS starts with liquid N 2O 4/NO 2, which is then converted in a proprietary Cassette to NO. The GENOSYL DS delivers NO into the ventilator stream, where the NO joins a stream of air or O 2and is diluted to the prescribed concentration.

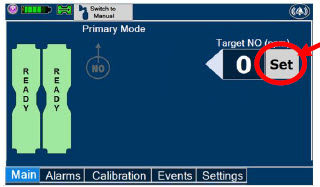

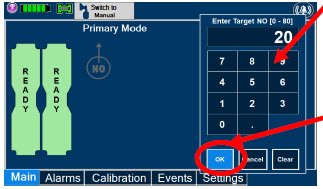

The NO concentration (dose) to be delivered to the patient is selected by the user and is set and maintained independently by means of computer-controlled air pumps, Cassette heaters, and a feedback loop that measures the delivered NO concentration.

The GENOSYL DS takes a gas sample removed from the NO gas flow stream immediately prior to the patient and provides real-time output of the NO, NO 2, and O 2concentrations that are being delivered to the patient. The continuous integrated gas monitoring includes a comprehensive alarm system.

The NO concentration detected from the sample line is used in a feedback loop to adjust the NO concentration delivered into the ventilator circuit.

The GENOSYL DS includes a redundant Console for complete back-up capability for delivery of NO for inhalation. Each Console has a back-up battery that is expected to last up to four hours under optimal conditions in the absence of an external power source. Console will alarm when less than 15 minutes of battery life remains.

GENOSYL DS. The GENOSYL DS continuously introduces a precisely controlled concentration of nitric oxide (NO) into the inspiratory limb of the ventilator circuit. GENOSYL DS utilizes the known properties of NO and other oxides of nitrogen, namely dinitrogen tetroxide (N 2O 4) and nitrogen dioxide (NO 2), to create a "tankless" drug/device combination System to produce, at the point of use, ultra-high purity NO for inhalation, providing a consistent, prescribed dose to the patient.

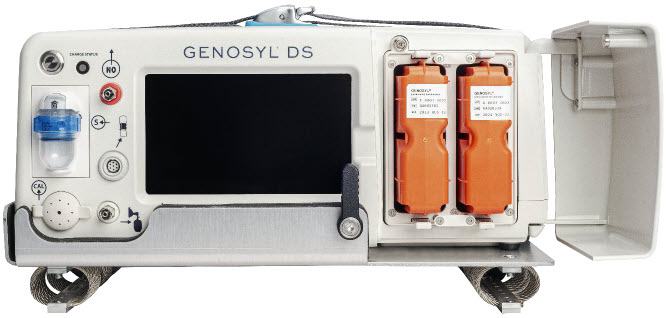

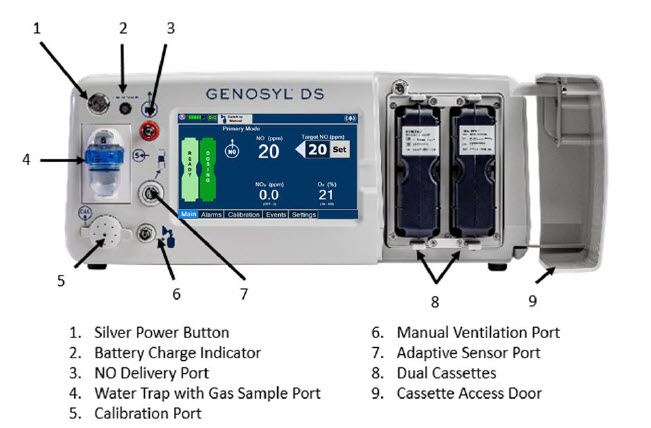

Console.The GENOSYL DS Console contains the electronics to control the production and to maintain the constant and precise delivery of NO.

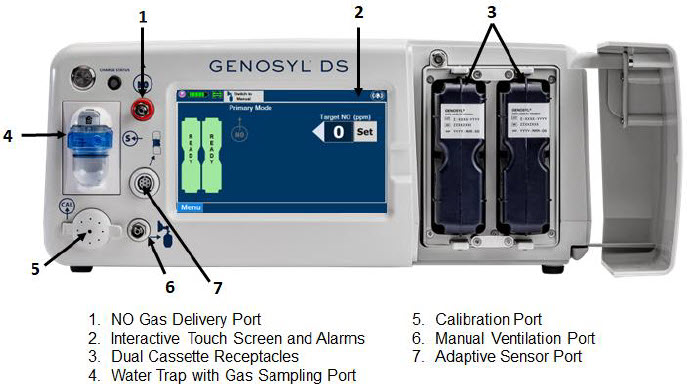

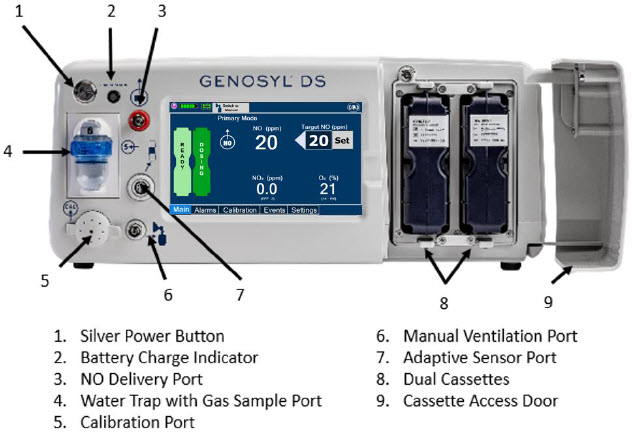

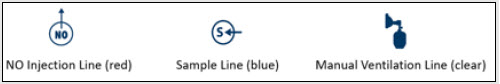

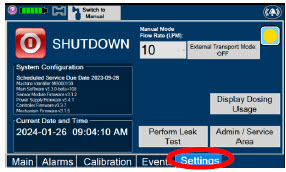

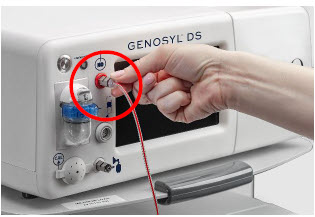

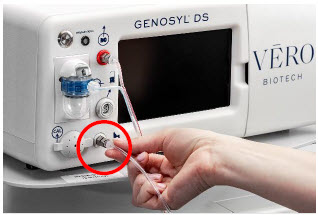

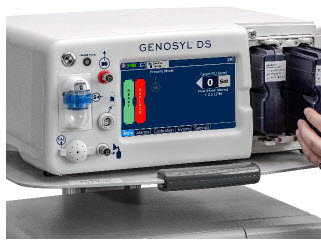

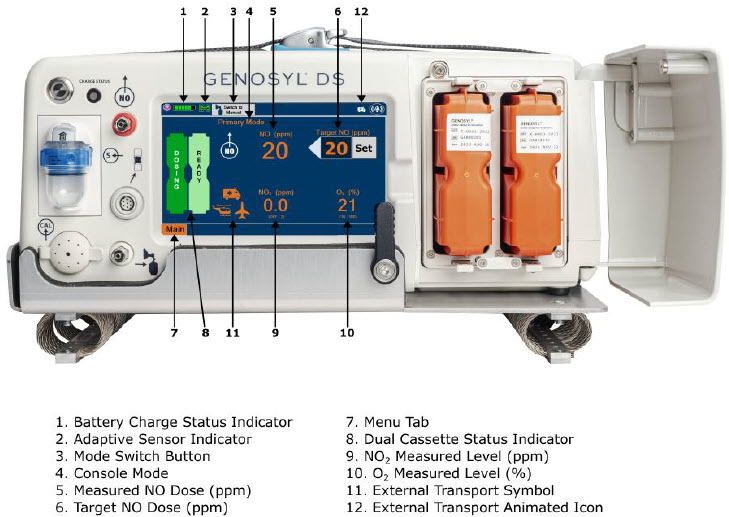

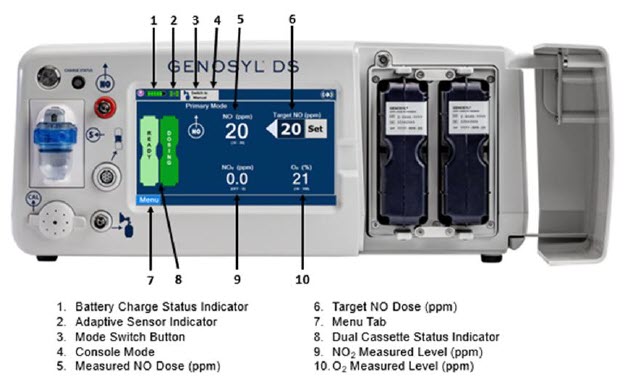

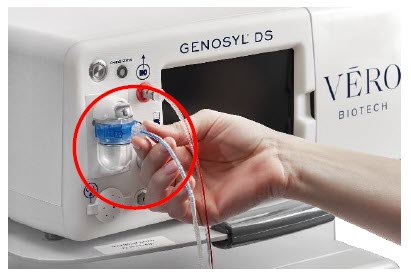

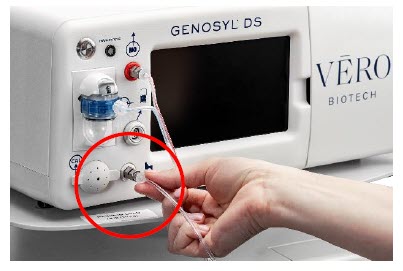

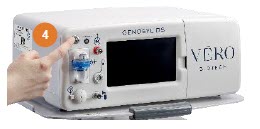

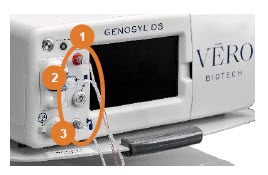

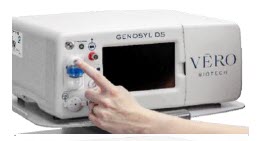

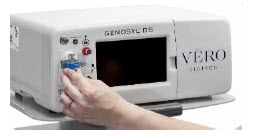

The primary features of the Console front panel are displayed in Figure 1.

NO generation.The Console uses Cassettes containing liquid N 2O 4/NO 2inside a stainless-steel vessel (the liquid module) and an antioxidant cartridge. Upon initiation of a Cassette, the liquid N 2O 4is heated, producing NO 2gas, which is mixed with up to 0.9 LPM ambient air supplied by the Console. The NO 2/air is injected into the antioxidant cartridge inside the Cassette, which converts NO 2to NO.

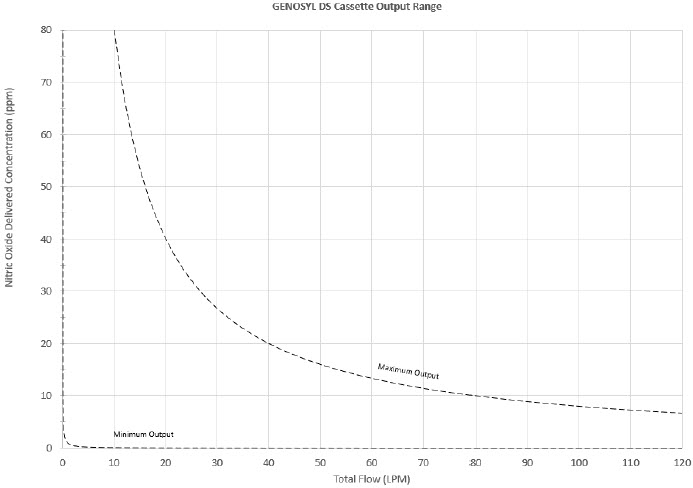

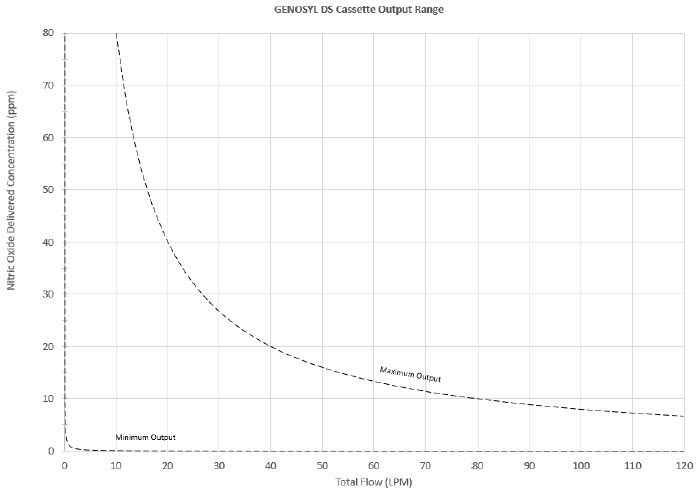

The Cassette is designed to provide NO in concentrations up to 80 ppm. The maximum and minimum delivered dose for a range of constant inspiratory flow rates is presented in Figure 2.

The maximum combination of dose (ppm) and flow (LPM) output of the System is 800 ppm × LPM (e.g., 20 ppm with 40 LPM, 40 ppm at 20 LPM, etc.). The System is capable of delivering NO at a minimum of 1 ppm × LPM (e.g., 1 ppm at 1 LPM).

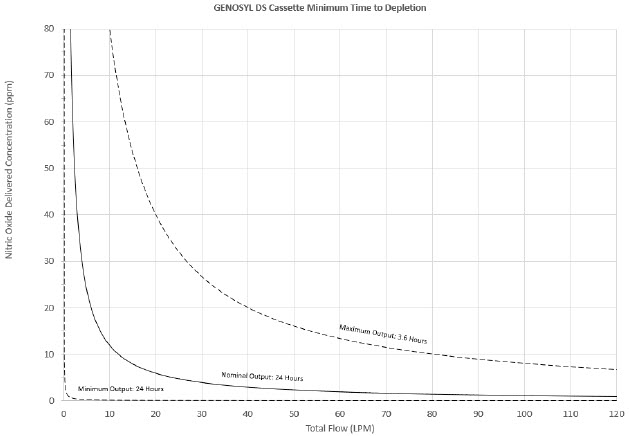

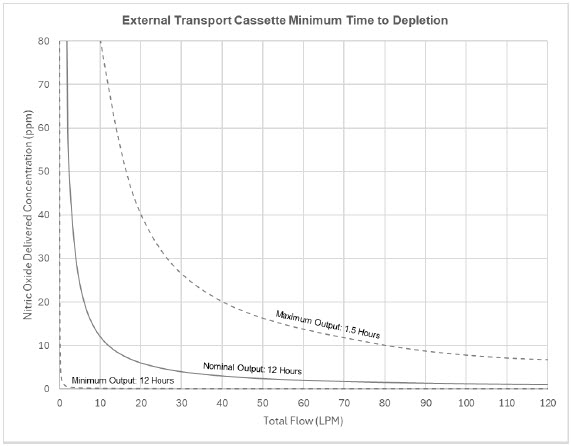

The total time to deplete the Cassette N 2O 4contents depends on the rate of use. The minimum time to depletion based on use rate for Hospital Cassettes is shown in Figure 3.The minimum time to depletion of the External Transport Cassette based on use rate is shown in Figure 4.The calculated minimum remaining contents at the current output rate is indicated by a gauge presented on the Console display during use.

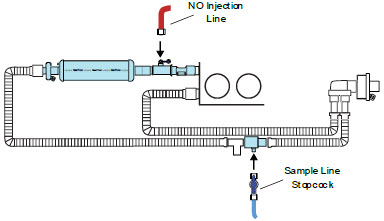

NO Injection into the Ventilator Circuit. After NO is produced in the Cassette, the NO injector introduces the concentrated NO into the ventilator circuit where the NO is diluted to the prescribed concentration (dose) and mixed with the O 2or air supplied to the patient.

GENOSYL Smart Feedback System ™Before the gas mixture reaches the patient, a sample line removes a small gas sample and sends it back to the Console, where gas sensors continuously measure the supplied NO, NO 2and O2. The Console software then compares the measured NO concentration to the set NO concentration and continuously adjusts the delivery of NO to maintain the prescribed NO concentration (dose) delivered to the patient (closed loop control). The Console software commands the NO injection flow rate into the ventilator circuit with a maximum flow rate of 0.9 LPM. Changes in the ventilator settings by the user may cause brief transient changes in the measured NO value. The Console software will adjust the injected flow rate and the internal temperature of the Cassette to compensate for the changes in the total ventilator flow rate. For example, a higher minute ventilation will require a higher injection flow rate to produce the same NO concentration.

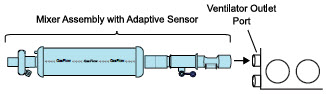

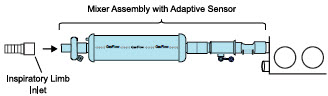

Mixer. An inline Mixer is used in the applicable ventilator circuit after the NO injection site and before the gas sample site to mix NO from the Console with the gas supplied by the ventilator, for specific ventilator and tidal volume use cases per Section 12.2.

Gas Monitoring.The gas mixture delivered to the patient by the GENOSYL DS is continuously monitored with two NO detectors, with one providing redundant back-up, as well as a detector for NO 2and O 2. A sample of inspired gas is taken from the inspiratory limb, close to the patient, and is measured by the gas sensor within the Console. The gas monitoring sensors are electrochemical; they are specific to each gas and provide an electronic signal that is proportional to the concentration of gas present.

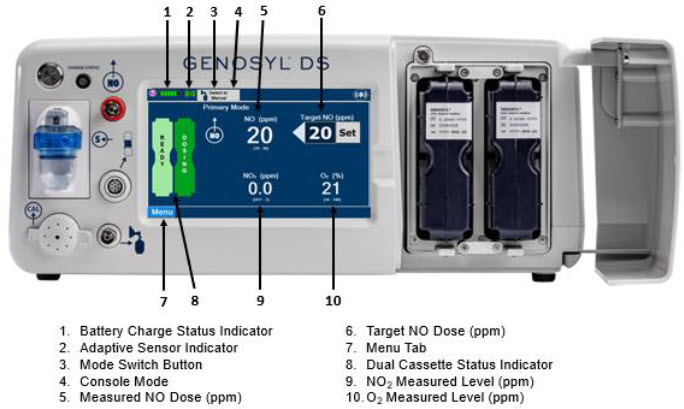

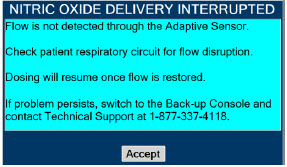

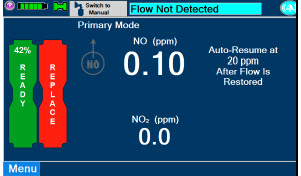

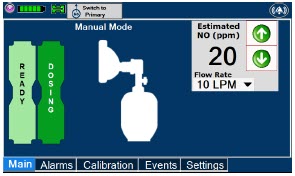

Adaptive Sensor.The Adaptive Sensor is used to detect flow in the patient breathing circuit. When flow is not detected by the Adaptive Sensor, nitric oxide delivery will be interrupted until flow is detected. The Console will provide a visual and audible low priority alarm when flow is not detected to alert the user (see Section 10.5). Once flow is detected, the Console will auto resume delivery of nitric oxide at the previously set dose. An Adaptive Sensor is recommended for use with certain breathing devices. Refer to Section 3for recommended set up diagrams. The GENOSYL DS will properly deliver and control nitric oxide dose in the absence of an Adaptive Sensor.

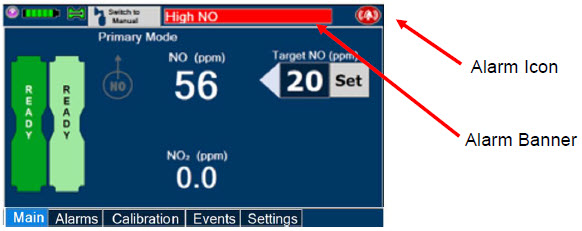

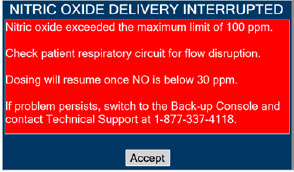

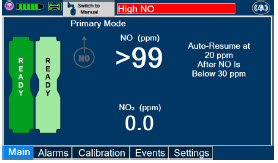

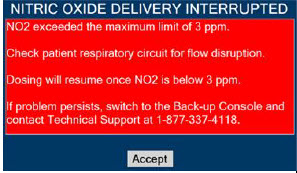

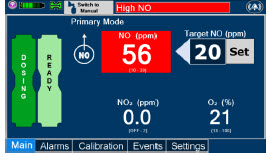

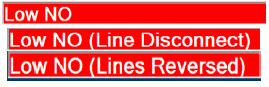

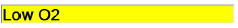

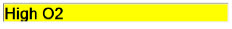

Alarms and Dosing Safeguard Fallback Modes.The GENOSYL DS alerts the user in the event of excursions of NO, NO 2, and Oxygen from their expected ranges. Nitric oxide delivery interruption conditions are as follows:

- NO > 100 ppm

- NO 2reaches 3 ppm

- The measured respiratory circuit dilution flow drops below 0.3 LPM as measured by the Adaptive Sensor.

The Console will provide a visual and audible high priority alarm. When detecting a sustained gas level higher than the above limits for 11 consecutive seconds, the Console will interrupt delivery of NO until the sampled levels of NO and/or NO 2decrease to a safe level. Once sampled levels are in acceptable range, the Console will resume delivery with previously set dose.

If the cause of the high gas cannot be resolved, the use of the Back-up Console may be required. Refer to Section 10.1for additional information on alarms and dosing safeguards.

If NO delivery was interrupted due to the GENOSYL DS Adaptive Sensor reading dropping below 0.3 LPM, the Console will resume delivery with the previously set dose once the Adaptive Sensor reading exceeds 0.35 LPM. The automatic resumption of dose delivery after the interruption conditions listed above are cleared is one of the safety fallback modes of the GENOSYL DS.

Back-up NO Delivery.The Back-up Console is used to administer nitric oxide when the Dosing Console cannot be used. This Console has a separate power supply, and at least one Cassette loaded and preheated. If the Dosing Console fails to deliver NO, the Back-up Console is ready to begin dosing to continue NO delivery.

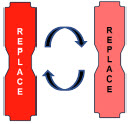

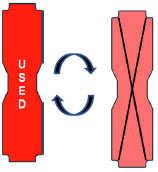

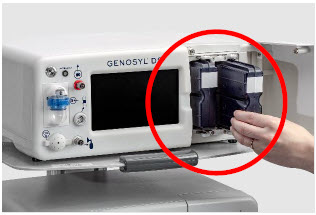

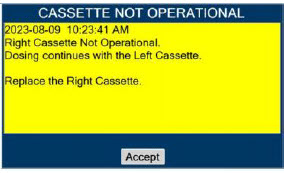

Transition to a new Cassette.When a Cassette approaches depletion, the Dosing Console will automatically transition to the second Cassette in the Console. Once the dosing Cassette is depleted, the Dosing Console will eject the depleted Cassette and alert the user to replace via the Cassette Status Indicator.

Disposal of the Cassette. Following use, any remaining Cassette contents are purged into an inerting chamber, where the contents are chemically neutralized, rendering the Cassette safe for disposal.

1.4 Exposure of Healthcare Providers to NO and NO 2

Occupational exposure of healthcare providers to NO or NO 2may occur during Inhaled NO therapy for patients. Below are examples of calculated and observed exposure to NO or NO 2, in the context of guideline workplace exposure limits.

Calculated and observational methods show that the exposure levels to NO or NO 2from an NO delivery system are significantly less than the levels recommended by the National Institute for Occupational Safety and Health (NIOSH).

Workplace Limits: NIOSH has recommended workplace exposure limits as follows 1.

NO time-weighted (8 hours) average concentration limit of 25 ppm NO 2 Recommended exposure limit of 1 ppm Theoretical Calculation.The build-up of NO in a well-ventilated ICU room, with NO flowing directly into the room, can be evaluated using the following calculation:

Room size 1000 ft 3 Room volume 28,300 L Room ventilation (6 complete exchanges/hour) 2,830 L/min NO flow into the room 80 ppm at 14 L/min Average NO room concentration 0.4 ppm of NO Observations of NO Exposure. The theoretical calculation has been supplemented by actual measurements in three independent studies in actual therapeutic use settings. 2,3,4The studies found that detectable exposures to NO and NO 2were brief, infrequent, and well below recommended exposure limits.

If the location for using NO has uncertain ventilation, then the location should be evaluated for NO and NO 2build-up prior to use.

GENOSYL ®DS

SECTION 2

SYSTEM OVERVIEWDetailed instructions are provided in this manual for the primary user interaction and frequently used functions of the GENOSYL DS, which include:

System Set-Up and Connections (Section 3)

- Connections to Various Breathing Systems

- GENOSYL DS Ventilator Circuit Assembly Pre-Check

- GENOSYL DS Injection Assembly with Adaptive Sensor

- GENOSYL DS Mixer Assembly with Adaptive Sensor

- GENOSYL DS Console Connections

- GENOSYL DS Gas Line Connections

- GENOSYL DS Sample Line Extension Connection

- GENOSYL DS Adaptive Sensor Cable Connection

- GENOSYL DS Ventilator Circuit Connection

- GENOSYL DS Manual Ventilation Connections

- GENOSYL DS Mechanical Ventilator Circuit Connections

- Gas Sampling During Aerosol Delivery

System Start-Up (Section 4)

- Console Start-Up

- Cassette Insertion

- Water Trap / Sample Line Leak Test

Nitric Oxide Administration (Section 5)

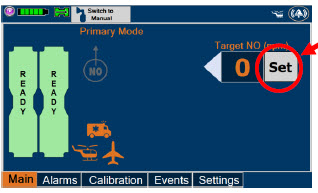

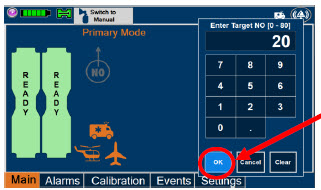

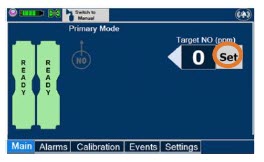

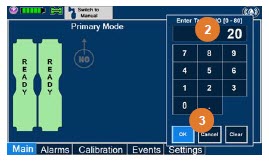

- Setting a Dose when using a Circuit with an Adaptive Sensor

- Setting a Dose when using a Circuit without an Adaptive Sensor

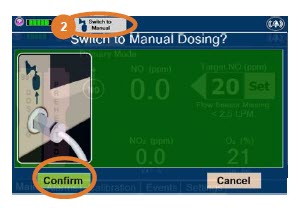

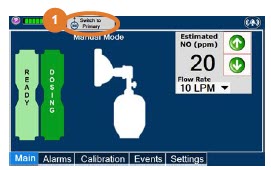

- Adjusting the Dose

- Manual Dosing Mode

- Manual Ventilation Use (Bagging)

- Preset Manual Dosing Mode Flow Rate (Optional)

- Resuming Primary Dosing

- Console Use as Back-up

Console Shutdown (Section 6)

- Console Shutdown

- Cassette Removal

- Cassette Disposal

Using the System in the MR Scanner Room (Section 7)

- Connection to the Ventilator Circuit

- Transferring to and from the MR Scanner Room

External Transport (Section 8)

- External Transport Set-up and Ventilator Circuit Schematics

- Using GENOSYL DS for External Transport

Use with an Anesthesia Gas Machine (Section 9)

- Connection to a Dual Limb Anesthesia Circuit

- Connection instructions for the GENOSYL DS to an Anesthesia Gas Machine

Alarms, Alerts, and Troubleshooting (Section 10)

- On-Screen Troubleshooting Module

- Alarms (High, Medium, and Low Priority)

- Informational messages

- GaussAlert™ Alarm

- Troubleshooting

- Leak Detection Tool

System Maintenance (Section 11)

- Calibration

- Maintenance Schedule

- Testing the GaussAlert™ Function

- Water Trap Maintenance

- Battery

- Cleaning

- Storage

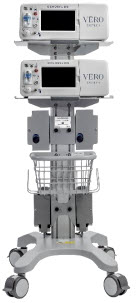

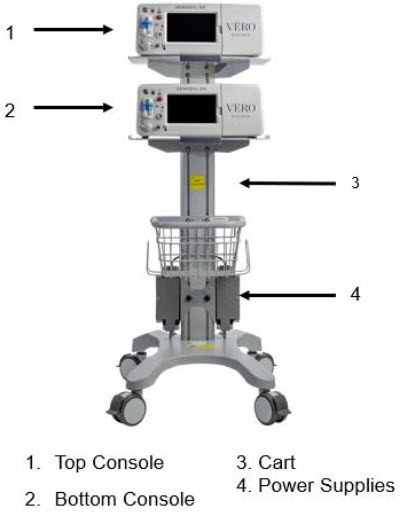

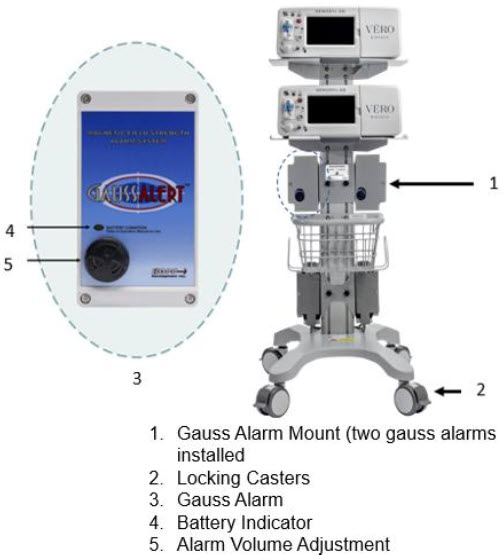

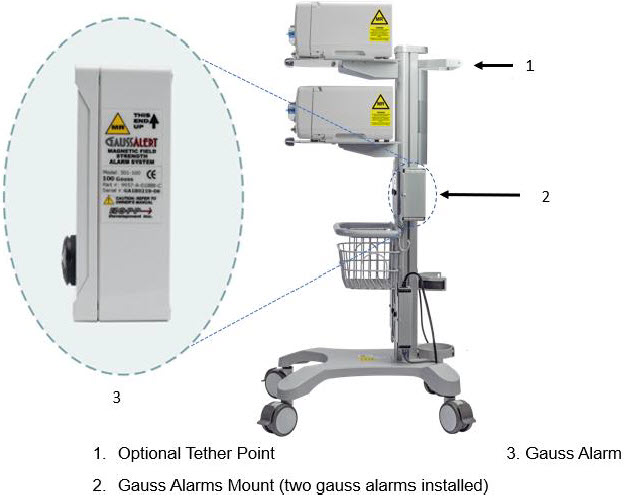

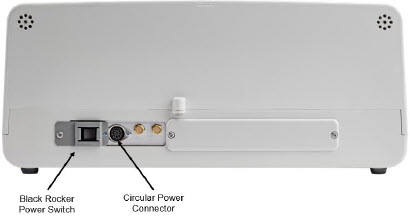

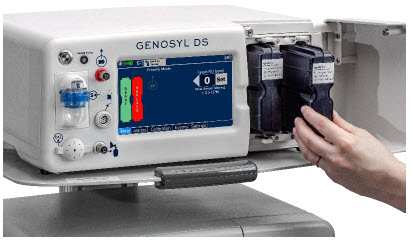

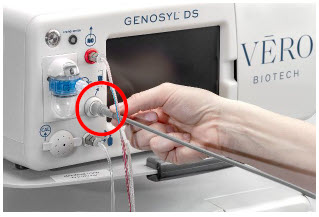

2.2 GENOSYL DS Cart and Consoles

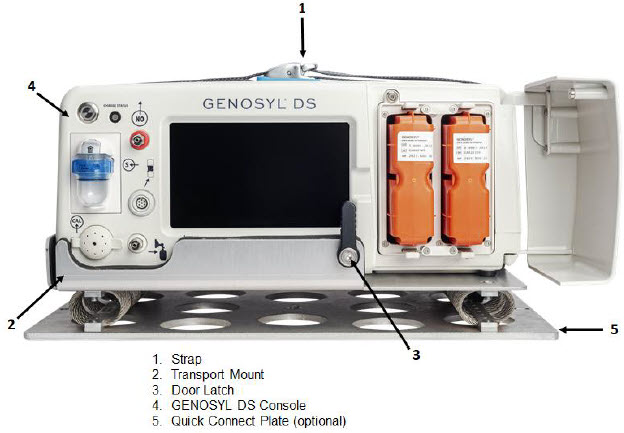

The following pages contain photos of the GENOSYL DS Consoles. The specific sections of the GENOSYL DS are numbered with the respective description listed below the photo.

WARNING - NEVER use the MR Unsafe GENOSYL DS Cart in the MR scanner room.

- ALWAYS verify at least one gauss alarm is functioning properly prior to use in the MR environment.

CAUTION - ALWAYS operate the Console on a level surface to avoid potential interruption to nitric oxide (NO) delivery.

- DO NOT stand or sit on the Cart. Standing or sitting on the Cart can damage device.

- ALWAYS push or pull the Cart using the handle only. NOT doing so may result in damage to the device.

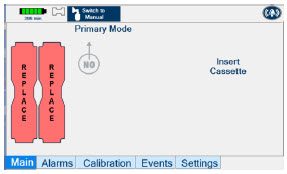

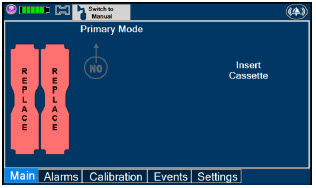

NOTE A System has a top and bottom Console. Both Consoles will start-up in Primary Dosing Mode. One Console will be used for dosing and the other will remain in Primary Dosing Mode as a Back-up Console. (SeeSection 5.5)

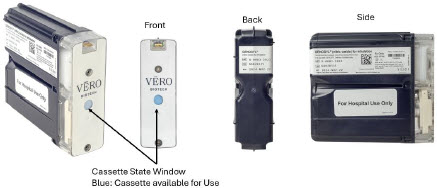

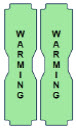

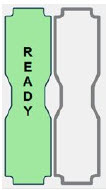

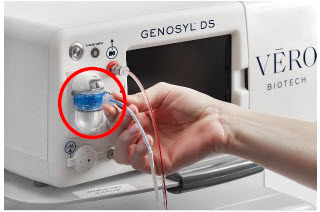

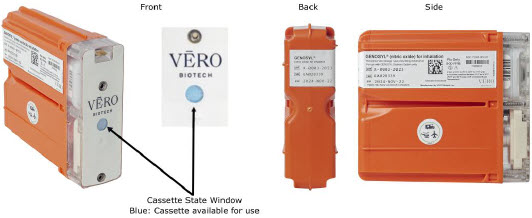

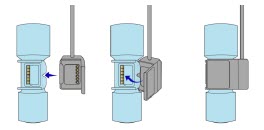

The Cassette contains the material that will be converted to nitric oxide during the activation process. It is inserted into the GENOSYL DS Console, and its shape helps ensure proper orientation during the insertion process. A Cassette State Window is located on the front of the Cassette to indicate if the Cassette is available for use (blue), or if it has been inerted and unavailable for use (bleached and reddened).

The GENOSYL DS requires different Cassettes for use in the hospital (ICU or MR setting of care) and for use in external patient transport. The Hospital Cassette is blue in color. See Figure 12for details about the Hospital Cassette. The External Transport Cassette is orange in color. Refer to Section 8for more information about using the GENOSYL DS in external transport and Figure 13for details about the External Transport Cassette.

Cassette in Packaging

Unused Cassette

Inerted Cassette

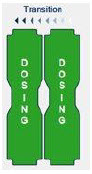

Figure 12: GENOSYL Cassette External Transport Cassette in Packaging

Unused External Transport Cassette

Inerted External Transport Cassette

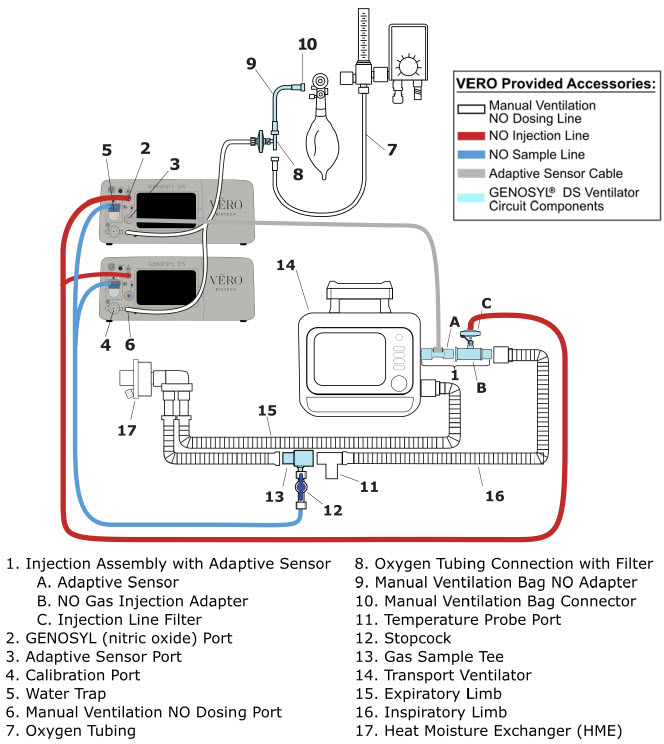

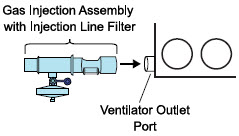

Figure 13: GENOSYL External Transport Cassette CAUTION DO NOT remove Cassette from packaging until ready to use. External packaging is designed to protect the Cassette from damage and/or contamination. 2.4 GENOSYL DS Ventilator Circuit Components

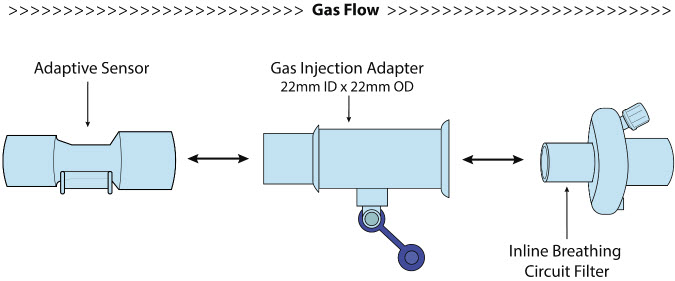

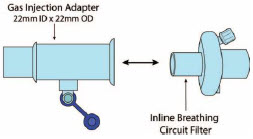

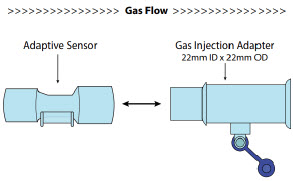

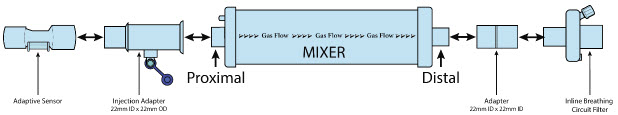

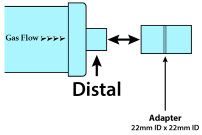

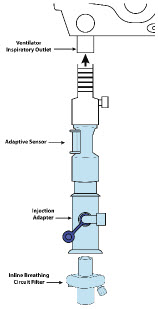

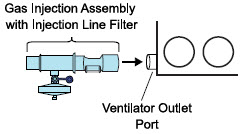

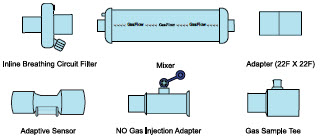

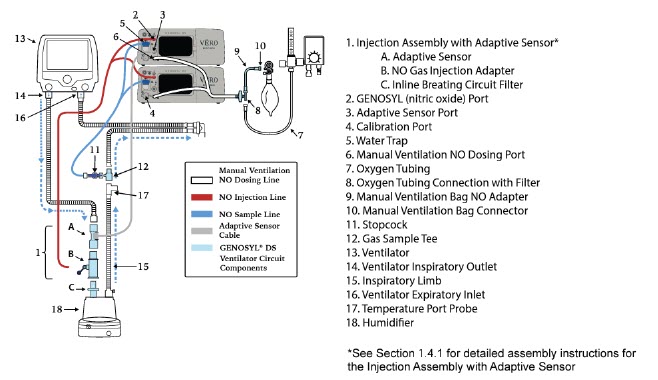

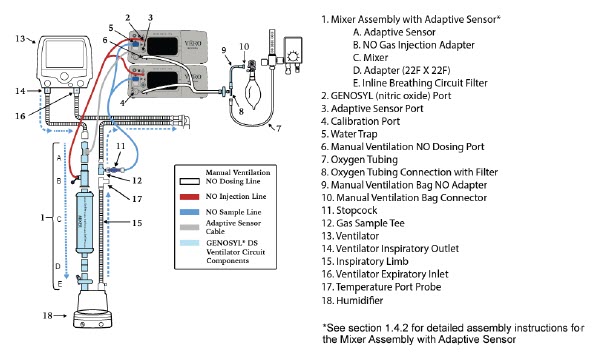

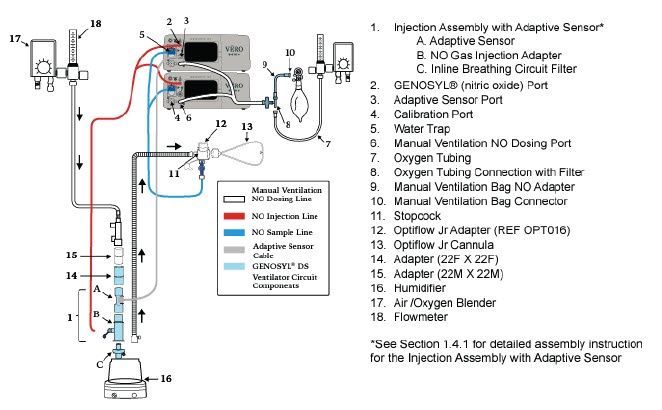

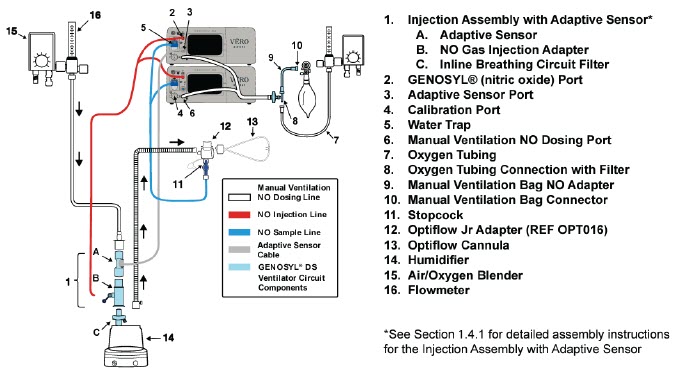

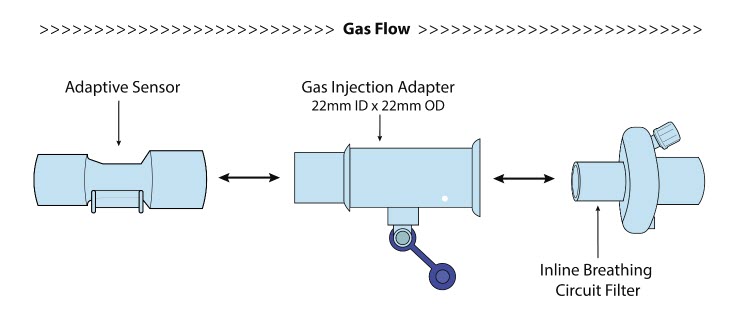

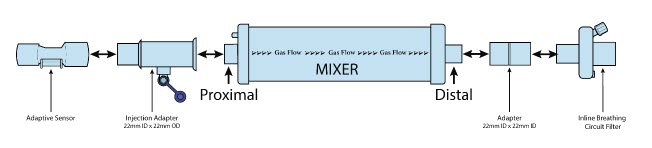

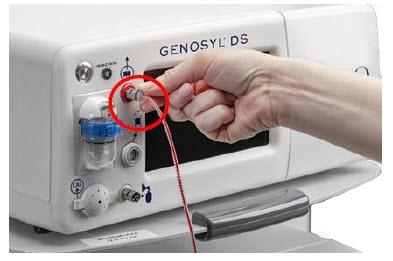

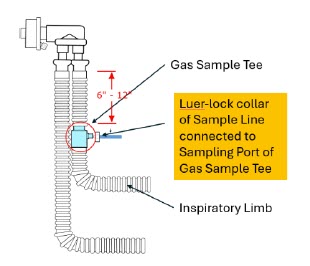

The following parts are used to set up the GENOSYL DS portion of the patient respiratory circuit, as specified in Section 3.2.

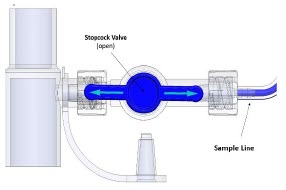

PART PART NAME FUNCTION

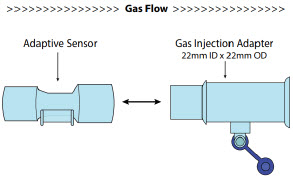

Adaptive Sensor Used to measure flow from the ventilator into the circuit.

Adaptive Sensor Cable Used to communicate flow readings to the Console.

GENOSYL DS Gas Lines

NO Injection Line (red)

Sample Line (blue)

NO Manual Ventilation Line (clear)Used to deliver nitric oxide to the ventilator circuit and manual ventilation bag, and to sample gas within the ventilator circuit.

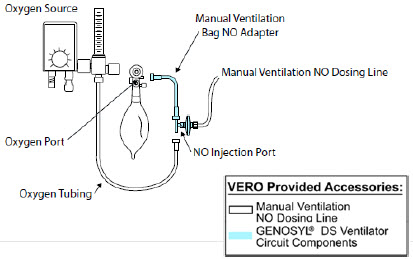

GENOSYL DS Manual Ventilation Bag NO Adapter Used to connect oxygen tubing to manual ventilation bagging system to deliver nitric oxide. Includes an NO Injection Port to connect to the NO Injection Line.

GENOSYL DS Mixer Used to mix the NO gas with the gas supplied by the ventilator through a filter containing silica gel to provide intra-breath NO delivery for certain scenarios.

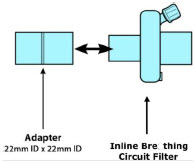

Adapter

22F × 22FUsed as a coupler between the Mixer and the Gas Injection Adapter when a Mixer is required.

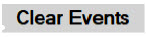

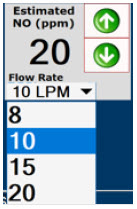

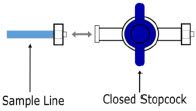

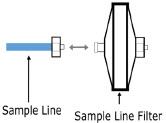

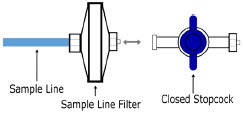

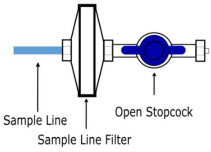

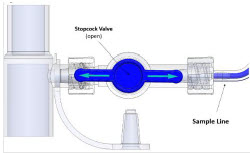

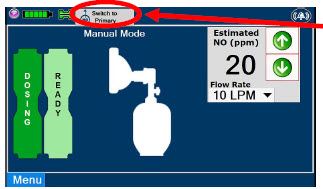

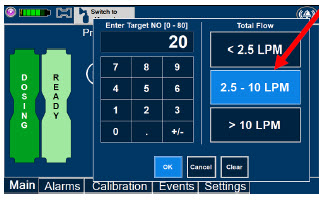

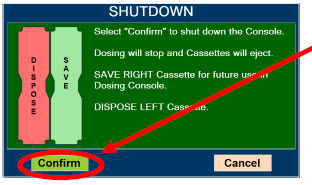

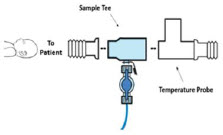

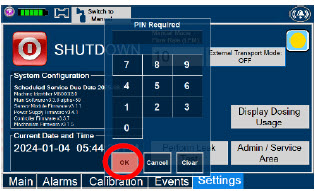

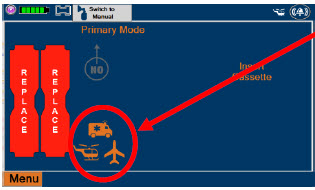

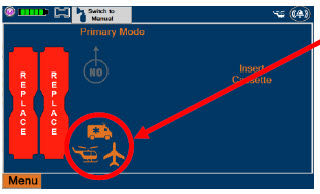

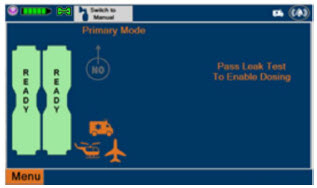

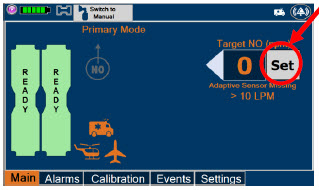

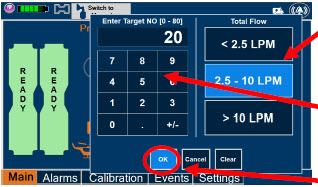

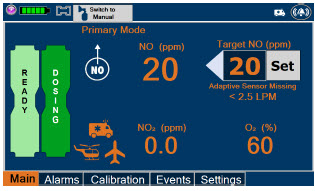

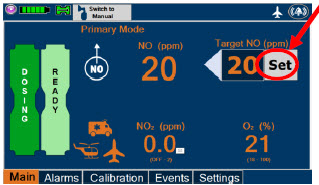

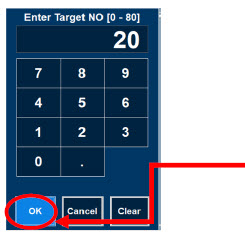

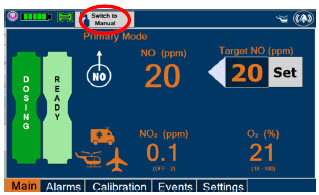

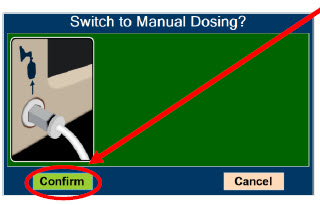

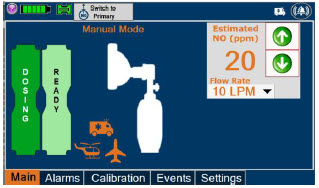

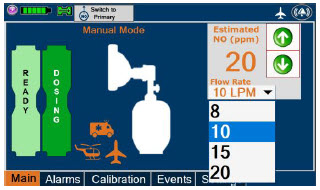

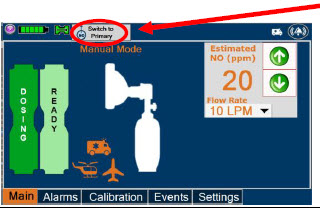

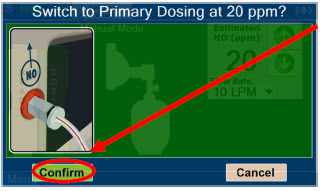

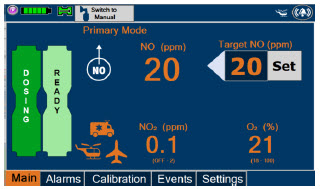

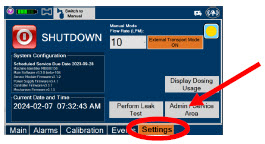

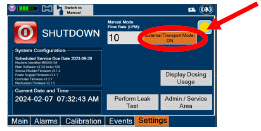

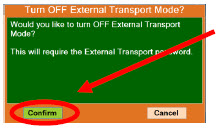

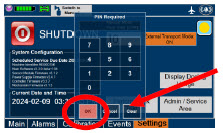

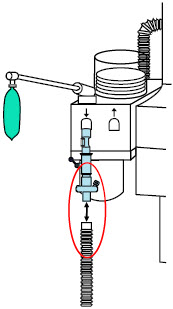

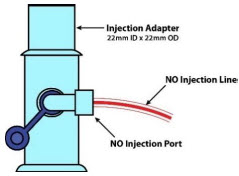

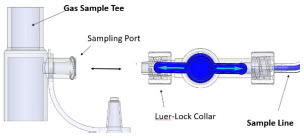

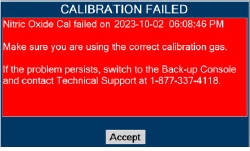

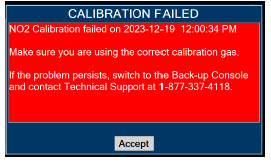

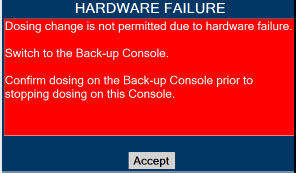

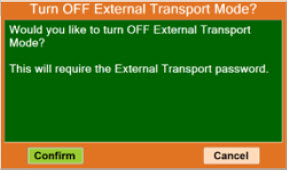

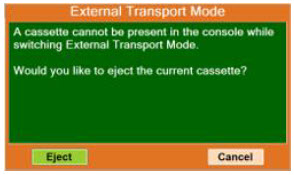

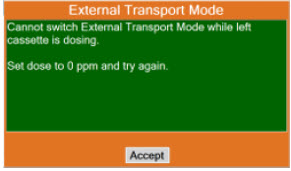

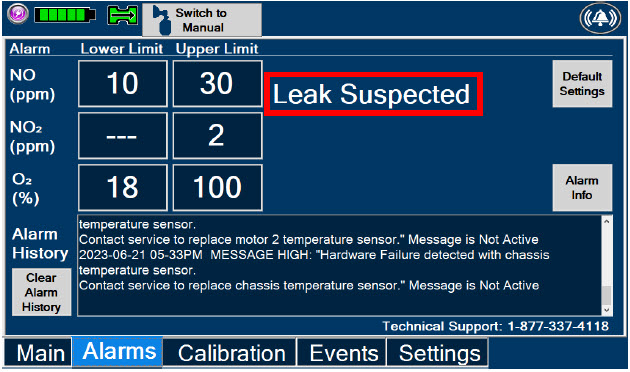

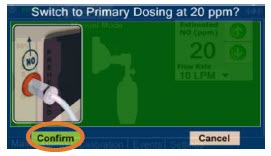

GENOSYL DS Sample Line Extension Used when the distance between the patient and the DS exceeds the length of the standard sample gas line in the MR Environment.